Understanding Cantilever Gate Systems

How Cantilever Gates Differ from Swing Gates

Cantilever gates work great for sliding smoothly back and forth, giving them some clear benefits compared to those old fashioned swing gates we all know. The way they function means there's no need for extra room where the gate would normally swing outwards, so they fit really well in tight spaces around properties. While regular swing gates pivot from one side, these cantilever models actually roll along tracks keeping them suspended just above the ground as they move. Because of this setup, they tend to last longer since there's less friction against the earth causing damage over time. Another reason why people love them? They handle tricky terrain much better than traditional options. Think about yards with bumps or dips in the ground, or places where trees or other objects might block normal gate movement. Cantilevers just glide right past those issues without a problem.

Core Components of a Cantilever Gate Kit

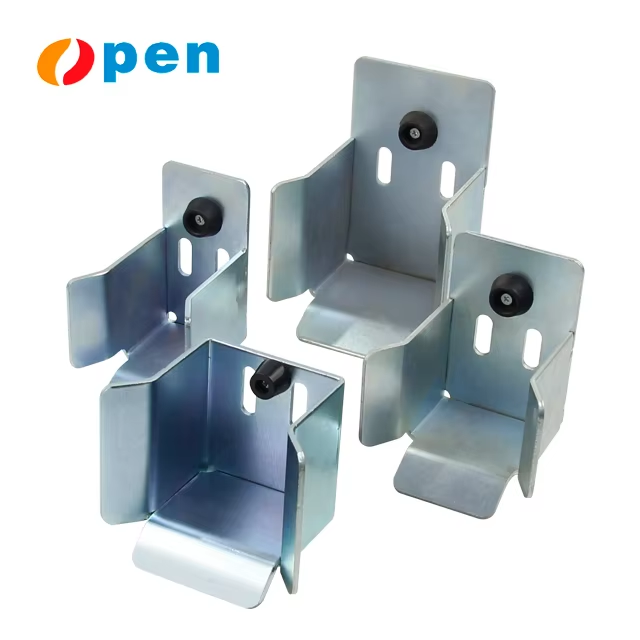

For a cantilever gate to work properly, there are several key parts involved including the gate panel itself, along with the track system, those little rollers that move along the tracks, plus the support posts that hold everything up. Getting familiar with what each part does makes all the difference when installing or fixing problems later on down the road. The quality of materials matters a lot too because cheaper stuff just doesn't last as long. We've seen gates fail prematurely simply because someone cut corners on materials. When looking at hinges specifically, go for heavy duty ones since they bear most of the load. And don't forget about track alignment either; even a small misalignment can cause big headaches over time. Spending extra money upfront on good hardware pays off handsomely in the long run, especially considering how much wear and tear these gates typically endure day after day.

By consistently prioritizing these components, a cantilever gate system can assure seamless functionality and enduring durability.

Key Factors in Selecting Your System

Site Preparation: Storage Space and Elevation Requirements

Getting a good look at the installation area before putting in a sliding gate system makes all the difference for how well it works over time. There needs to be enough room for the gate to actually move back and forth smoothly, plus space left when it's fully open so nothing gets blocked off. The ground level matters too. If there's a slope or bumps in the area where the gate goes, this can cause problems down the road. Gates on uneven ground tend to jam up or wear out faster than those on flat surfaces. Most folks don't think about it until later, but checking local building codes and getting proper permits upfront saves headaches later on. Nobody wants to deal with fines or having to tear something apart because they missed a regulation requirement.

Gate Opening Width and Weight Capacity

Picking out a sliding gate system means looking at two main things first: how wide the opening needs to be and what kind of weight the gate can handle. Getting the right width matters a lot when vehicles need to pass through, especially if bigger trucks or equipment will be going in and out regularly. Sometimes standard sizes just won't cut it, so we end up needing something custom made. Materials matter too. For heavier duty gates, steel construction makes sense while lighter aluminum works fine for smaller installations. Cheap materials often fail under stress, leading to constant fixes down the road. That's why talking directly with manufacturers about weight limits helps pick the right electric opener for any given situation. Most people find this approach saves money in the long run since they avoid buying gear that breaks down too soon.

Understanding Cantilever Gate Systems

How Cantilever Gates Differ from Swing Gates

Cantilever gates work differently than regular swing gates because they slide along instead of swinging open. Swing gates need plenty of room to swing around in an arc shape, but cantilever models just glide straight across. That makes them perfect when there's not much space available near the entrance area. The way these gates are built keeps them floating slightly above the ground surface thanks to special rollers underneath. This setup means less damage happens over time since the gate doesn't rub against the ground as much. We've seen this be particularly useful in places where the terrain isn't flat or where there might be trees, shrubs, or other landscape features that would get in the way of normal gate operation.

Core Components of a Cantilever Gate Kit

Cantilever gate kits generally come with four main pieces: gate panels, tracks, rollers, and support posts. These parts all work together to make sure the gate goes up properly and runs smoothly day after day. When picking out materials for these components, durability matters a lot because cheaper options tend to wear out faster than quality ones. Most homeowners overlook this aspect but end up spending more money down the road on repairs. Heavy duty parts matter too. Strong door hinges prevent sagging over time while proper track alignment keeps everything running without sticking or grinding noises. Gates that are built with these considerations last much longer and require far fewer adjustments compared to those cut corners on construction specs.

Infill Materials and Durability Considerations

Ornamental vs. Chain Link Infill Styles

When picking between ornamental and chain link infill for a gate, the choice really affects how functional and attractive the gate will be. Ornamental options give that fancy look while keeping things private, so they work great when someone wants both style and secrecy around their property. But let's face it, these tend to cost quite a bit more than chain link alternatives that focus on letting people see through them and saving money at the same time. Think about where the gate will actually sit too. Some ornamental designs hold up better against rain and sun damage if made from quality materials with good finishes. At the end of the day, what matters most depends entirely on why someone needs the gate in the first place. If privacy is key then one type makes sense, but if looking for something affordable yet still decent looking another option works better. Each situation calls for different materials based on what exactly needs to get done.

High-Security Options for Restricted Areas

Security conscious facilities need strong materials and modern tech to keep things safe and intact. Gates made with reinforced steel or composite fillings stand up better over time while being harder to break into, which makes them great choices for areas where security matters most. Adding good locks plus camera systems really boosts protection levels, something businesses dealing with lots of people or expensive stuff should seriously consider. Getting input from actual security experts helps customize the whole gate setup so everything works together properly around the property. Picking the correct options isn't just about looking good it actually makes sense for anyone worried about keeping their place secure against potential threats.

Automation and Heavy-Duty Operation

Integrating Electric Sliding Gate Openers

Electric sliding gate openers bring real improvements to property access while boosting security levels at the same time. When picking out an opener, go for something heavy duty that matches what the gate can handle in terms of size and weight. Otherwise there will be problems down the road with operation. There are different power options available for these systems. For folks with properties located far from main power lines, going solar makes sense environmentally and cuts down on dependency on regular electricity supplies. Getting a professional to install these things is pretty much essential nowadays. They know how to set everything up right so nothing gets damaged later on. A good install job means better performance overall and saves money in repairs because gates last longer when done properly from the start.

Self-Locking Mechanisms for Enhanced Security

Self locking mechanisms are really important when it comes to making sliding gates more secure because they lock automatically when the gate closes, stopping people from getting in without permission. Many of these systems work with remote controls or even smartphone apps now, which makes them super convenient but still keeps things pretty safe. This kind of tech is especially useful for businesses and big properties where security matters a lot. The catch though? Like any mechanical system, they need checking from time to time. Parts do wear down eventually and that can create gaps in security. A quick monthly inspection goes a long way toward keeping everything working properly. When those locks function as intended, property stays protected and folks don't have to worry about someone sneaking through late at night.

Installation and Long-Term Maintenance

Ground Clearance and Track Alignment

Getting the ground clearance right and making sure the tracks are properly aligned when installing a sliding gate matters a lot for how well it works and how long it lasts. Enough space between the ground and the gate lets it move freely without scraping along the surface. This becomes really important where there's snow buildup or lots of dirt and leaves around. Without enough clearance, gates get damaged faster and need expensive fixes down the road. Track alignment isn't something to overlook either. When tracks aren't straight, they create extra friction that wears out parts quicker than normal. We've seen gates fail completely after just a few months because someone skipped this step during installation. Checking these things regularly makes all the difference. A quick look at the clearance and an occasional adjustment keeps everything running smoothly for years instead of weeks.

Lubrication and Component Inspection Cycles

A regular schedule for lubricating and checking your sliding gate system will make it last much longer than if neglected. When we apply lubricant to those moving parts like rollers and hinges, it cuts down on friction which wears things out over time. For folks living in places where winters get really harsh or summers bring lots of humidity, keeping that lubrication going is super important. Without proper treatment, metal parts can freeze together or start rusting away. Checking everything regularly makes sure nothing is stuck or broken. Keeping track of what gets done when helps spot problems early on before something breaks entirely. Taking care of maintenance this way keeps gates working smoothly while saving money in the long run since nobody wants to deal with expensive emergency repairs during bad weather.