Core Mechanism of Cantilever Gate Operation

Cantilever gates design is trackless and carrier wheels on gate hold 40-50% of weight extends beyond the opening covered. A gate with this overhang will keep its shape while it slides effortlessly on a higher track that is attached to a post. The gate's bottom is fitted with steel rollers that glide along the track, and the gate itself has guide wheels to prevent lateral drift. Like the previous model, this mechanism is suited to tricky terrain as it does NOT have ground obstructions like traditional sliding gates.

Key Components Included in a Cantilever Gate Kit

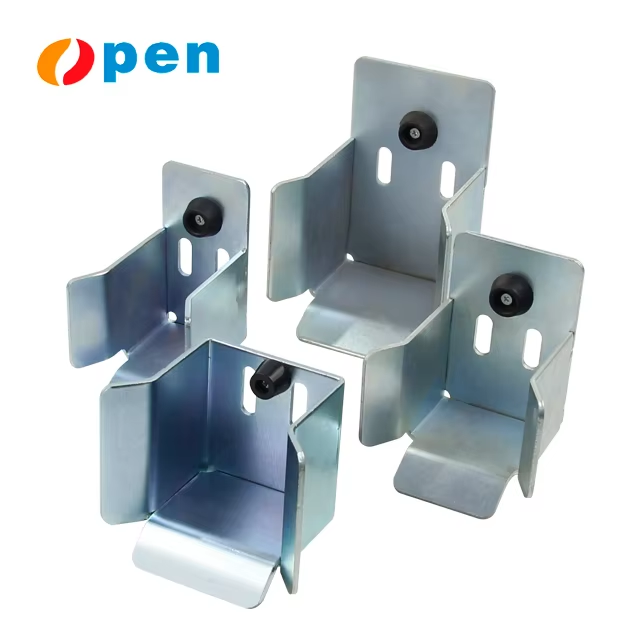

Every cantilever gate kit contains these essential parts:

- Carriage rollers: Bear the gate’s weight and facilitate movement (typically 2–4 units)

- Guide wheels: Maintain alignment during operation

- Adjusting plates: Allow precise horizontal/vertical positioning

- End stoppers: Prevent over-travel damage

- Structural steel beams: 8–12 ft horizontal supports and vertical posts

- Counterbalance framework: Reinforced section extending beyond the opening

- Track system: Heavy-duty channel for rollers, mounted on support posts

This system requires 30–50% less ground space than conventional sliding gates and performs reliably in temperatures from -20°F to 120°F.

Top Advantages of Choosing a Cantilever Gate Kit

Smooth Operation Without a Ground Track

The trackless design eliminates friction and debris buildup, ensuring consistent performance in snow, mud, or gravel conditions. Tests show counterbalanced rollers operate up to 38% more smoothly than tracked alternatives (2023 Commercial Fencing Study).

Excellent Performance on Uneven or Sloped Terrain

These gates adapt seamlessly to slopes up to 15 degrees, with 68% of sloped installations using cantilever kits (2024 Gate Industry Group survey).

Durability and Long-Term Reliability

Galvanized steel frameworks and enclosed rollers protect components from weather. Manufacturers report lifespans of 12-15 years, outperforming swing gates by 40% in corrosion testing (2023 Material Longevity Report).

Minimal Ground Clearance Issues

Suspending the gate 4-6 inches above ground prevents snowplow collisions and vegetation interference, reducing clearance-related repairs by 90% (2023 Commercial Property Maintenance Analysis).

Ideal for High-Traffic Driveways

Industrial-grade kits support over 200 daily operation cycles without performance loss, handling 1,500+ lbs of continuous load (2024 Industrial Access Solutions Study).

Common Disadvantages and Limitations

Higher Initial Cost Compared to Swing and Roller Gates

Cantilever kits cost 20-35% more upfront due to robust structural requirements. A standard 16-foot residential kit averages $3,800-$5,200 installed versus $2,400-$3,600 for swing gates (Gate Security Report 2023).

Space Requirements for the Cantilevered Overhang

These systems need 2-3 feet of clearance beyond the gate opening, limiting installations on narrow urban lots. The cantilever's horizontal footprint exceeds ground-tracked gates by 40-60% (Industrial Fencing Standards 2024).

Complex Installation Needs

Professional installation is often required due to precision alignment needs. Even minor errors in post angles or counterbalance adjustments can cause operational issues. Most manufacturers void warranties on DIY installations.

Installation, Maintenance, and Long-Term Care

Best Practices for Foundation and Post Installation

Dig footer holes 36–48 inches deep and pour 3,500–4,000 PSI concrete. Use laser levels to align posts within 1/8-inch tolerance. Allow 28-day concrete cure before attaching hardware.

Routine Maintenance: Lubrication and Inspection

Bi-annual lubrication with lithium-based grease reduces friction by up to 70%. Inspect for loose bolts, debris accumulation, and test automated components. Look for rust streaks or irregular noises as early warning signs.

Managing Wear on Rollers and Support Structures

Replace nylon roller inserts every 5–7 years or when grooving exceeds 1/16-inch depth. Reinforce steel hangers with galvanized plating if pitting occurs. Recalibrate counterweights annually for sloped installations.

How Cantilever Gate Kits Compare to Swing and Sliding Gate Systems

Cantilever vs. Traditional Swing Gates

Cantilever systems slide horizontally without ground contact, eliminating gate sagging (reported in 68% of swing gate installations). They provide:

- Zero ground interference

- 85% less snow/ice jamming

- Self-stabilizing hangers for seasonal ground shifts

Cantilever vs. Roller Sliding Systems

| Feature | Cantilever Gate | Roller Sliding System |

|---|---|---|

| Track Required | No | Yes |

| Debris Vulnerability | Low | High |

| Max Span Capacity | 60 ft | 40 ft |

| Ideal Application | Heavy industrial/commercial | Light residential |

Cantilever systems last 3-5x longer between component replacements than sliding gates with ground tracks, with 42% lower long-term maintenance costs.

FAQ Section

What is a cantilever gate kit?

A cantilever gate kit is a package that includes all the necessary components for installing a cantilever gate, which slides horizontally without a ground track, making it ideal for uneven terrain.

How does a cantilever gate operate?

Cantilever gates operate using a trackless design where the gate slides on higher tracks and is supported by carriage rollers. This setup prevents ground obstruction and suits uneven terrain.

What are the advantages of choosing a cantilever gate?

Cantilever gates offer smooth operation without ground interference, adaptability to sloped terrains, durability, minimal ground clearance issues, and suitability for high-traffic areas.

Are there any drawbacks to installing a cantilever gate?

Yes, cantilever gates have a higher initial cost, require space for overhang clearance, and often need professional installation due to complex setup requirements.

How do cantilever gates compare to swing gates?

Cantilever gates eliminate ground contact during operation, provide less interference from snow/ice, and automatically adjust to seasonal ground shifts compared to swing gates.

What is the difference between cantilever and roller sliding systems?

Cantilever systems do not require a track, have lower debris vulnerability, manage larger span capacities, and are better suited for heavy industrial and commercial applications compared to roller sliding systems.

Table of Contents

- Core Mechanism of Cantilever Gate Operation

- Key Components Included in a Cantilever Gate Kit

- Top Advantages of Choosing a Cantilever Gate Kit

- Smooth Operation Without a Ground Track

- Excellent Performance on Uneven or Sloped Terrain

- Durability and Long-Term Reliability

- Minimal Ground Clearance Issues

- Ideal for High-Traffic Driveways

- Common Disadvantages and Limitations

- Higher Initial Cost Compared to Swing and Roller Gates

- Space Requirements for the Cantilevered Overhang

- Complex Installation Needs

- Installation, Maintenance, and Long-Term Care

- Best Practices for Foundation and Post Installation

- Routine Maintenance: Lubrication and Inspection

- Managing Wear on Rollers and Support Structures

- How Cantilever Gate Kits Compare to Swing and Sliding Gate Systems

- Cantilever vs. Traditional Swing Gates

- Cantilever vs. Roller Sliding Systems

- FAQ Section