Why Heavy Duty Sliding Door Rollers Matter in Commercial and Residential Applications

Critical Role of Heavy Duty Sliding Door Rollers in High-Traffic Environments

Sliding door rollers built for heavy duty applications cut down on friction during operation by around 52% when compared to regular systems according to the WSD Industry Report from 2022. This makes them particularly valuable in places where doors get opened and closed constantly throughout the day like big warehouses and busy retail stores. The tough construction can handle door weights going well beyond 1200 pounds as noted by Skysen Fence in their 2023 findings, plus they keep working properly even after being cycled through more than 100 times each day. Many businesses that switched to these heavy duty versions have seen components last about 40% longer while spending roughly 63% less money fixing alignment issues. What really stands out is how these durable designs stop track wear before it starts, especially since most problems with frequently used doors come from weight not being distributed evenly across the tracks.

Enhancing Accessibility, Safety, and User Experience Through Smooth Operation

According to a 2022 WSD research report, engineered rollers can boost glide consistency as much as 70%. This makes them great for meeting ADA requirements in public spaces across the country. People who work with heavy doors find they need to put in about 25% less effort to open them these days, which means fewer strains and sprains on the job. For places like restaurants and hospitals, stainless steel versions stand up well against all those cleaning sessions without rusting or wearing down. When it comes to homes, there are special silent roller options out there now that cut down door noise around 30 decibels. Makes a big difference for folks living in older houses getting updated for better access, especially when families want grandparents to stay safely in their own homes longer.

Engineering Design of Heavy Duty Sliding Door Rollers for Optimal Load Support

Load-Bearing Mechanics and Weight Capacity in Tandem Roller Systems

When it comes to tandem roller systems, they work by spreading out the weight over several wheels instead of putting all the pressure on just one spot. For businesses using these systems commercially, each individual roller is rated for around 350 pounds of load capacity. And guess what? Tests show this setup actually moves things along smoother than traditional single wheel models too. According to some research published in Hardware Engineering Journal back in 2023, we're talking about roughly 40 percent better performance there. The way these systems are designed helps spread out forces more evenly across whatever surface they're rolling on. This matters because when force isn't distributed properly, certain areas get stressed out way too much which eventually causes problems like warping or getting knocked off alignment completely.

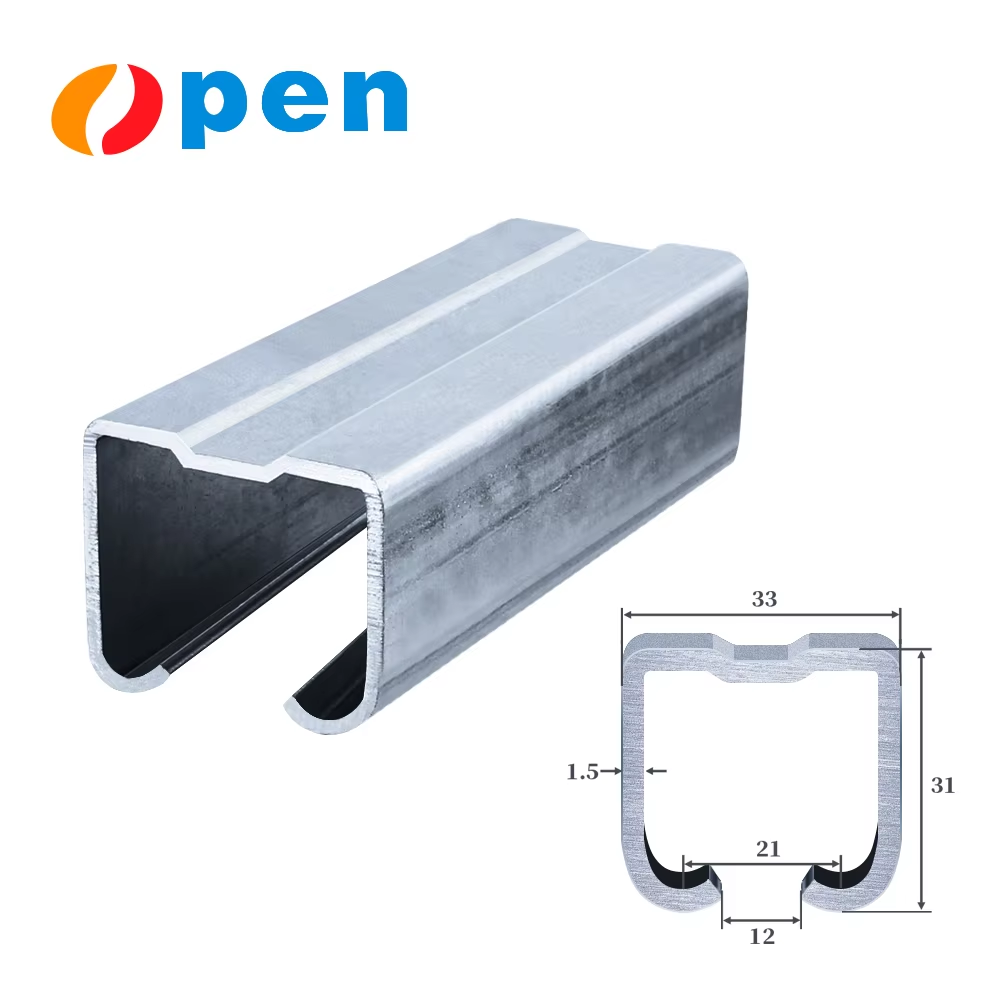

Steel Ball Bearing and Concave Roller Design for Reduced Friction

Heavy duty rollers today incorporate steel ball bearings featuring concave profiles that cut down on rolling resistance quite effectively. The difference between these and regular flat wheels is pretty substantial actually. When those concave shapes match up with their tracks properly, they manage to slash friction levels around 55 percent according to lab testing standards. What makes these bearings stand out further is the quality of materials used. Made from premium grade steel hardened at about 60 HRC, they keep working reliably even after going through more than 100 thousand operating cycles without needing any kind of lubrication. This characteristic makes them especially good choices for places where maintenance needs to be minimal such as medical facilities and storage centers where downtime can really disrupt operations.

Anti-Sagging Mechanisms and Balanced Weight Distribution in Heavy Doors

To counteract sagging in doors over 300 lbs, engineers incorporate adjustable tension springs and reinforced housings. Positioning rollers 24"–36" apart limits vertical deflection to ≤0.1" under maximum load. Precision alignment reduces track wear by 70% compared to non-adjustable systems, preserving long-term structural integrity and system reliability.

Materials and Durability: Choosing Long-Lasting Heavy Duty Sliding Door Rollers

Stainless Steel vs. Reinforced Polymers: Comparing Strength and Wear Resistance

When deciding between stainless steel and reinforced polymers, what matters most is how the material will be used. Stainless steel can take around 750 pounds per roller according to research from International Materials Institute back in 2023. This makes it really strong stuff that doesn't bend or deform easily when subjected to heavy weights. On the other hand, materials like glass filled nylon have their own advantages. These polymer options cut down track wear by about 40 percent in places where things aren't too heavy duty, plus they soak up vibrations pretty well. Because of this property, these plastics work great in environments where noise control is important, think hospitals or other quiet spaces where excessive sounds need to stay at bay.

Corrosion Resistance for Outdoor and Humid Environments

When it comes to coastal areas or industrial settings, 304 grade stainless steel rollers hold up really well too. After spending 5,000 hours in that ASTM B117 salt fog test, they still maintain around 98% of their original strength, which actually meets those tough marine durability requirements. Now for places where there's lots of moisture, think swimming pool areas, polymer rollers coated with zinc aluminum stuff work great because they don't rust and don't need any kind of lubrication either. And interestingly enough, when manufacturers embed ceramic into these polymer mixtures, the lifespan gets extended by about 60% in environments where things get washed down regularly but stay pH neutral overall.

Long-Term Performance Under Constant Use and Maintenance Demands

The lifespan of these components depends heavily on keeping those roller shapes accurate as they age. Airport terminals tend to see high carbon steel rollers lasting around twelve years before needing attention, whereas polymer alternatives in retail stores usually need replacing after just seven years due to different usage patterns. According to research published last year in the field of logistics, switching to stainless tandem rollers cut down on alignment problems by nearly three quarters compared to traditional single wheel setups. Warehouse managers should pay special attention to sealed bearing housings since they stop dirt and debris from getting inside where it causes most premature failures. This kind of maintenance really makes a difference in long term operational costs.

Performance Features That Enable Smooth and Quiet Sliding Door Operation

Noise Reduction Technologies in Modern Heavy Duty Sliding Door Rollers

Manufacturers now incorporate nylon composites along with various polymer blends in their roller designs specifically for noise reduction purposes. According to research from Ponemon back in 2022, nylon rollers can cut down on noise levels by around 30% when compared to traditional metal options. Some advanced models even feature precisely machined polymer treads that absorb shocks and vibrations, resulting in about a 10 decibel drop in overall noise. This matters quite a bit in places like hospitals where patients need quiet environments, libraries requiring concentration spaces, or office settings where constant background noise disrupts workflow and employee focus throughout the day.

Precision Engineering for Seamless Glide and Long-Term Reliability

Roller alignment within 0.1mm tolerances prevents uneven wear, extending hardware life by 5–7 years in high-use areas. Self-lubricating materials like PTFE-coated bearings lower friction coefficients to 0.05–0.1, enabling effortless movement even under 1,200+ lb loads. Encapsulated steel ball bearings maintain performance through 200,000+ cycles by blocking dust and debris.

Real-World Impact: Lower Maintenance Costs in Commercial Facilities

A 2023 Facility Management Report found that optimized rollers reduced door-related repair costs by 40% over 18 months. Anti-vibration designs prevent track warping and misalignment—two leading causes of system failure. Facility managers also reported 72% fewer lubrication interventions annually, reducing labor costs and minimizing operational disruptions.

Integrating Heavy Duty Rollers with Track and Pulley Systems for Peak Performance

Matching Rollers with Track Alignment for Smooth, Wobble-Free Movement

Precise alignment between rollers and tracks is critical for reliable operation. Even 1–2 mm mismatches in groove diameter can cause lateral movement or accelerated wear in doors over 500 lbs. Tapered roller profiles now offer self-centering capabilities, compensating for minor track imperfections common in industrial installations.

Pulley System Influence on Door Balance and Operational Efficiency

Pulleys redistribute 30–40% of a door’s weight, reducing strain on rollers. Dual-bearing pulley systems lower torque requirements by 24% compared to single-pivot models (2023 Mechanical Engineering Analysis), allowing facilities to cycle doors more than 200 times daily without excessive wear—particularly beneficial in warehouse dock operations.

Ensuring Compatibility Between Rollers, Tracks, and Door Hardware Fittings

A 2024 industry survey revealed that 63% of early system failures result from mismatched components. For example, pairing stainless steel rollers with aluminum tracks can cause chatter due to hardness differences. Engineers recommend verifying four key parameters:

- Load ratings (static and dynamic forces)

- Thermal expansion coefficients for outdoor use

- Lubrication port alignment with track access

- Bolt thread patterns securing rollers to door carriages

This holistic approach extends hardware life by 5–7 years in demanding environments such as marine terminals and refrigerated storage facilities.

FAQ

What makes heavy duty sliding door rollers suitable for commercial use?

Heavy duty sliding door rollers are designed to handle high friction and heavy weight capacities, suitable for places with frequent door use such as warehouses and retail stores.

How do engineered rollers improve safety and accessibility?

Engineered rollers enhance glide consistency and reduce required effort for operation, making them ideal for meeting ADA requirements and reducing strain injuries.

What are the benefits of using stainless steel versus reinforced polymers for rollers?

Stainless steel rollers offer superior strength and durability for very heavy doors, while reinforced polymers provide noise reduction and are excellent for environments where sound control is essential.

How does the pulley system contribute to sliding door efficiency?

The pulley system redistributes weight, reducing strain on rollers and allowing more efficient cycling, especially advantageous for high-traffic settings like warehouses.

Table of Contents

- Why Heavy Duty Sliding Door Rollers Matter in Commercial and Residential Applications

- Engineering Design of Heavy Duty Sliding Door Rollers for Optimal Load Support

- Materials and Durability: Choosing Long-Lasting Heavy Duty Sliding Door Rollers

- Performance Features That Enable Smooth and Quiet Sliding Door Operation

- Integrating Heavy Duty Rollers with Track and Pulley Systems for Peak Performance

- FAQ