Essential Cleaning Techniques for Tracks and Wheels

Removing Surface Debris from Sliding Door Tracks

If you want a clean and efficient sliding door, it is necessary to clean the tracks. Start by gathering a few necessary cleaning tools — choose a vacuum with a brush attachment, a microfiber cloth, and some gentle cleaning solution. You'll be able to clean the dirt and grime without damaging the door track. Start with a soft vacuuming of the track to eliminate any loose dirt, dust, and other debris that may impede the gates from sliding smoothly. It's an important first step in loosening larger debris before a deep clean. Give the track a good wipe with a damp microfiber cloth, pulling it into the corners where dirt can get stuck after you’ve vacuumed. It is also necessary to look for rust or corrosion as they can make the door work less efficient.

If there’s still those really hard dirt and food that simply won’t budge, combine warm soapy water again for that extra cleaning. But do be careful to not over-saturate this track to prevent left over moisture from developing rust. And that is something that is a great overall time-saver, and a hassle reducer – preventing bigger issues from occurring with the tracks on your sliding door and maintaining the proper condition of the track over a longer time period, minimizing the interruptions you have while using it.

Deep Cleaning Stubborn Grime on Wheels

Proper cleaning:Quick and easy way to clean all the wheel sets of your home roller blades First check them if wheel is visible grime/dust that need to remove so as to not block the wheel turn. If the wheels are not integrated, you may have to carefully extract them from the sliding gate motor. This makes it easier to reach areas usually not covered during normal cleaning. Take a soft brush or an old toothbrush and dip into soapy water to clean off any grime and grease. This method concentrates on breaking down the heavy grime without harming the actual wheels.

If there’s some extra-tough grunge on there, you may want to try a dedicated wheel cleaner. Adhere to the manufacturer's users manual to ensure that you do not harm the wheels. This is not only a great way to clean but a great way to maintain the longevity of your sliding door parts and overall health of your door. The regular maintenance of cleaning the wheels protect against wear and tear and keeps the system in reliable and smooth operation, no matter if you need this for automatic gate operators for sliding gates for businesses or homes.

Effective Lubrication Strategies for Smooth Operation

Choosing Silicone-Based Lubricants for Durability

Sliding doors While silicone-based lubricants are effective for keeping your sliding doors in good working condition because of their longevity and resistance to water. These are moisture-banishing lubricants, perfect for applications in high humidity areas. Silicone does not stain and will not attract dust, so lubrication is cleaner and slides are more efficient. Furthermore, you should always test compatibility with fittings such as brass and stainless steel hinges prior to use. In doing so, we can secure no adverse effect on the life and performance of them. For more specific alternatives, label recommendations might offer even more specific advice for various materials.

Proper Application to Avoid Dust Accumulation

Proper lubrication also aids is keeping dust off and the door moving free and easy. First of all, you should lubricate each side of the track and wheels by coating them as thinly as you can. This light application can lower risk of dust and debris buildup while being worn and worked in. Half-time best to underlube, avoid too much lube as it can offset the effect from excessive lube to sticky dirty surfaces. You should reapply lubricant during routine maintenance to further extend the life of those areas which are subjected to frequent use. This prevents the door from breaking and binds the door into a easy sliding movement, making the door toomuch tight will directly cause the door to push the roller offit is rail anddamagecompletely the trracl.

Inspecting and Replacing Worn Rollers

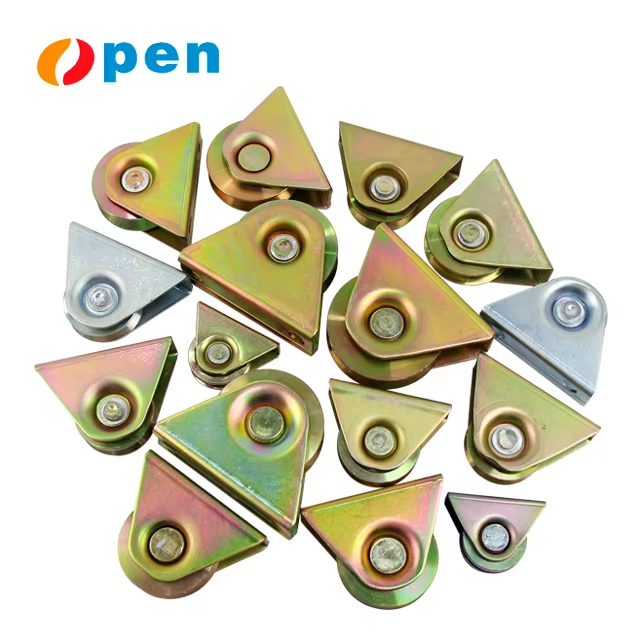

Identifying Damaged or Corroded Rollers

Rollers are a big part of what makes sliding doors work, so keeping an eye on them is key. I do inspect my rollers regularly for any sign of wear, e.g. any abnormal sound, that the roller does not turn perfectly true any more or I see clearly visible corrosion. These are important signals that the rollers may require some maintenance. Knowing the warranty terms of product such as heavy-duty sliding gate openers saves me from unexpected bills when a replacement is needed. I also have set up a regular maintenance schedule, following the manufacturers recommendation where things like all bolts are tight and any issues with rollers are not breaking down early on. The benefits of this proactive maintenance are not just that the doors work as efficiently as they should, but when it's more of an industrial environment the heaving usage it can help prolong their life too.

Step-by-Step Roller Replacement Guide

Door roller replacement can be intimidating, but it not as difficult as one might first think when broken into steps. Step 1) Get the tools you need before starting Always get prepared with all the needed tools, such as screw drivers, rollers for replacement, and if necessary, safety gloves, to help you with the replacement. First, remove the door track to expose the worn rollers. After the old rollers are out the new ones are installed with care to ensure they are in alignment inside the track where they should be for the best operation. It is essential to fasten them firmly, before re-assembling the door so that there is nothing in the way of a smooth, snag free slide. With routine check-ups and replacing of parts, my doors are keen to operate smoothly and operate without a hitch when it comes to sliding gate motors and automatic gate openers.

Adjusting Track Alignment for Seamless Movement

Proper track alignment is important for ease sliding of the doors. Symptoms of misaligned tracks are looseness in the sliding door, or large gaps at the edges. These are caused by constant use and possible obstructions in the channel. The procedure is to loosing the screws concerned with the track misalignment, readjust it to align the same again and to screw it up tight once again. After that, regular inspections to ensure vacant sliding door runs smooth is recommended. This regular maintenance work prevents common problems capacities of sliding doors and is very important for greased gate systems with gate running gear Heavy.

Caring for Stainless Steel Hinges and Brass Components

Regular lubrication for hinges and other door parts is important to avoid rust and maintain operational consistency. The stainless steel hinges and brass parts need to be cared for their own way. Use mild nonabrasive soap and a damp sponge to clean these stainless steel hinges to keep them shiny and free from rust. Brass components, on the other hand, gets to enjoy a combo of lemon and baking soda as a form of natural cleaning. The use of suitable lubricants may help to keep this relatively high-speed device functioning smoothly. Corrosion inhibitors must be used on stainless and brass parts in order to increase their life and maintain operation. This proactive maintenance helps keep the sliding door and the mechanisms connected to it operational.