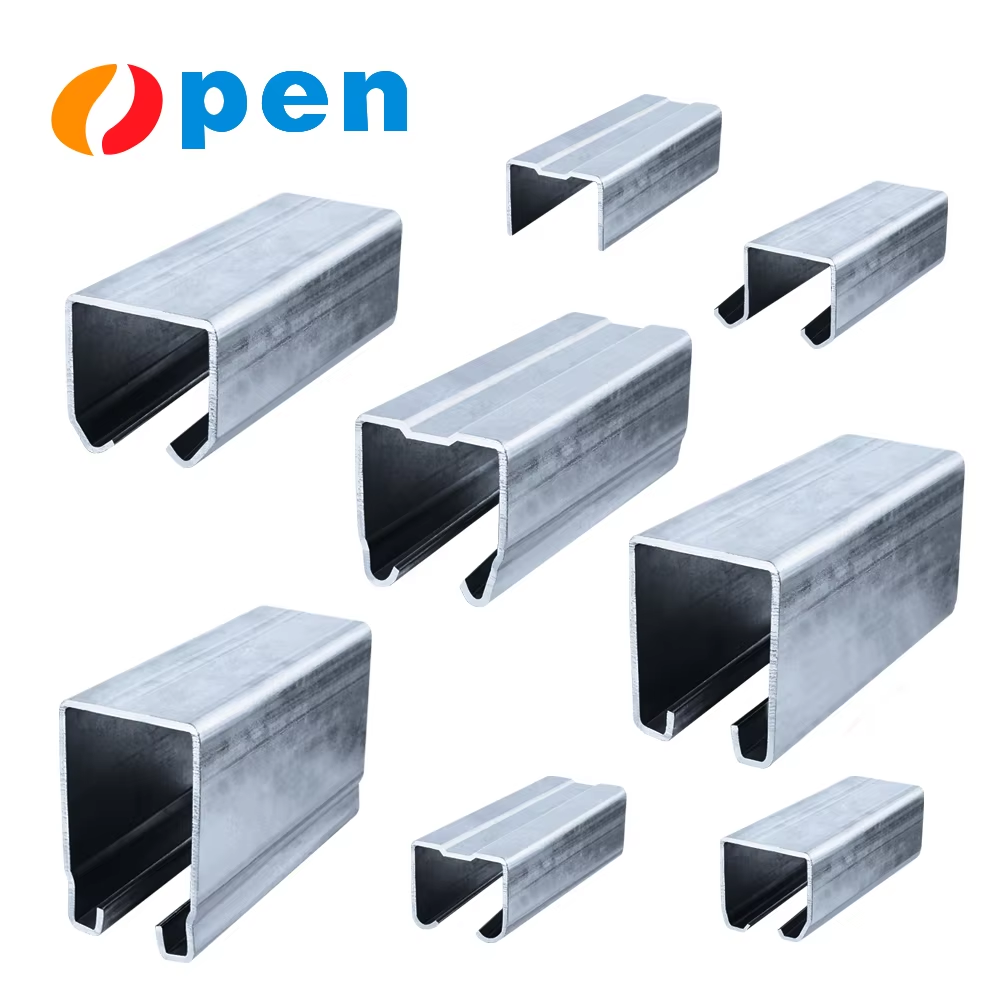

זיהוי אי-הסכמה ברצועות דלתות שולחות

סימני אי-הסכמה במסלול

הדלת המחליפה לא תוכל להיפתח או להיסגר אם יש אי-התאמהמה במסילות, ולכן важно כל כך לתפוס את הסימנים מוקדם. חפשו אי-הומוגניות בין הדלת עצמה לבין המסגרת, שכן השונות כאלה עלולות להצביע על מסילה לא מאוזנת, ובכך על בעיות במכניקה.ßerdem, אם הדלת נתקלת בהתנגדות או מושכת כשתנסו להזיז אותה, זה עשוי להיות סימן שהמסילה לא מאוזנת או שנוסדה בצורה לקויה. קולות במהלך הפעולה יכולים גם להדגיש בעיות: לשמוע גירוד או חיכוך מצביע על כך שהגלגלים נעולים או לא יושבים כמו שצריך,... ושהמשטח של המסילות נכנס לבעיה. לכן, אפשר למנוע את הידרדרות הבעיה לאורך זמן ושמר על פעולת התיק ההמשך.

בדיקה של זרימת תנועת הדלת

מבחן תנועה בסיסי יכול לתת לך מושג של כמה טוב דלת הקישוט שלך אמורה לעבוד. פשוט שחל את הדלת קדימה ואחורה והיא צריכה להזוז בקלות, ללא חיכוך. אם אתה מרגיש כל סוג של חיכוך או תנועות לא חלקות, זה סימן שיש אולי בעיות התאמה. אם דלת נתקעת תוך כדי שימוש, חשוב לגלות למה וזה עשוי להיות כתוצאה מסליל שלא בשורה. המבחנים עוזרים למנוע לדלתות קישוט בעיות פוטנציאליות לתקן יותר מתוקף.

בדיקת הזזות מבניות

דלתות שולחנות ושינוי מבנה דלתות שולחנות עלולות להושפע. זה עוזר לבדוק את המבנים הסובבים כדי לראות אם הם ישבו או נדחקו, מה גורם לאי-הסכמה במסלול. ייתכן שהוספתם משהו או עשיתם גרדיים סביב החוץ של הדלת השולחת, מה משנה את מה שהיסודות תומכים בו. שימוש במפל הוא טריק גדול לאתר בעיות מסגרת - בדקו את הרמה משני הצדדים של חלק ישר של מסלול, וההבדלים יגידו לכם שיש בעיה שתזדקק לטיפול. באמצעות בדיקת הקומפוננטים האלה, אנו יכולים להגן בצורה יעילה על הדלתות השולחות שלנו מפני섭וקים אפשריים.

העתקת גלגלים להתאמה נכונה של מסילת רכב

גישה לסכרים של העתקת גלגלים

הגיעו למתגמי הגלגלים הוא השלב הראשון בדרך לדלת שזזה חלקות. מתגמי הגלגלים נמצאים בדרך כלל בתחתית הדלת, אך זה יכול להשתנות בהתאם לדלת. במקרה זה, יותר חשוב להשתמש בכלים נכונים כמו מסתור פיליפס או מפתח אלן כדי למנוע את קריעת ראש המתגים. עשויים גם להיות צורך להפריד לגמרי את הדלת כדי לקבל גישה טובה יותר למתגים. זה הכרחי כדי להתאים את הדלת בצורה מדויקת עבור התאמה מעולה ונסיעה חלקה.

העלאת/הורדת גובה הדלת

התקנת דלת שולחנית היא חשובה כדי שהדלתות יעבדו חלקות. עושים זאת על ידי סיבוב מסCREW adjustment השיניים של הגלגלים עם כיוון השעון להעלות את הדלת, ונגד כיוון השעון להוריד אותה. תקינות התיקונים לגובה נדרשת כדי לוודא שהדלת נותרת בקשר אחיד עם הגלגלים כך שלא יהיה פער גדול מדי או כוח יורד רב מדי שיגרום לה לעבוד בצורה לא נכונה. לאחר שבוצעו התיקונים האלה, דחוף את הדלת פתוחה וסגור כדי לבדוק שהיא זזת חופשי ולא מתחככת או מתנגשת עם המסגרת.

בדיקת תנועה לאחר התיקון

אחרי זה, השתמשו בהזדמנות כדי לבצע בדיקה של הדלת המחליפה כדי לראות אם כל דבר התאמה מחדש בצורה תקינה. פתחו וסגרו את הדלת שוב ושוב ושמעו אחר קולות חדשים או מגבלות שעשויים להצביע על בעיות תחתוניות. החליפת הדלת לאורך מסלול לא צריכה להיתן התנגדות או תחושה של דבקות WHILE חליפה. גם ודאו שהדלת מאוזנת כשאתם פותחים וסוגרים את הדלת. מוט הבקרה הוא טוב אם הרכב רץ בצורה יציבה לאחר שינוי התאמות וזה אומר שהגלגלים הקדמיים והאחוריים (והתאמה) הוגדרו בצורה נכונה, מה שמהווה תוצאה מושלמת של כל תחזוקת סליל. הדלת יכולה להימשך זמן רב יותר ולהיות פונקציונלית יותר אם הדלת נבדקת באופן קבוע.

ניקוי ומעורר של מערכת המסילה

הסרת אבק עם כלים מיוחדים

השימור על המסלולים של הדלת השולפת שלך הוא חיוני לפעולה חלקה. קודם כל, ודא שלא נותר שום שאריות במסלול באמצעות מטיפת בית או סכין תחזוקה. זה יכול להיות פשוט כמו להריץ חיבור קטן של מטיפת על המסלול עצמו. ובנוסף, השערות הקשות שלו גם יוכלו לעזור להשיג את החלקים הקשים יותר. כך שומרים על פניית המסלול ללא פגיעה אך מבצעים פעולת טיהור. תחזוקה רגילה למסלולים היא דרך טובה לשלוט בהצטברות החומר שיכולה לגרום לדלת לא לפעול בצורה יעילה.

שימוש במספרים לפלדה[]={0} כדי להסיר צמיגים קשים

לפעמים, אבק צובר והופך לקשה להסרה באמצעות שיטות ניקיון רגילות. במקרה כזה, מברשת סטainless steel יכולה להיות כלי שימושי לניקוי גורף מוחלט. מברשות הן משהו שאפשר להשתמש בו רק אם אתה גם זהיר מאוד כדי לא להשאיר קעקועים על המסלול או על הגלגלים. ניקיון מeticulous של חומרים זרים מהמסילות מבטיח שהדרכים יעבדו בצורה יעילה ויתן למערכת דלתות מתחלפות חיים ארוכים יותר וביצועים משופרים. זו תהליך שניתן להוסיף בקלות לרשימת התחזוקה הרגילה שלך, וזה יעזור לך לשמור על המסילות נקיות ועובדות זמן רב.

הmacen של משח מסיליקוני

כדי לשמור על דלת הזזה שלך פועלת כראוי, בחירת חומץ סיליקון מתאים הוא המפתח. סוג כזה של חומרי סיכה הוא דוחה מים ומספק מחסום נוקשה נגד קורוזיה לשימוש ארוך טווח. לאחר ההתקנה, לשמן את המסלול ואת הגלילים באופן שווה כדי להבטיח תפקוד חלק. חומרי סיכה מבוססי שמן אינם מומלצים בשל נטייתם למשוך מלוכלך וזוהם (שעלול להרוס את מערכת הדלת המזחלת). השימוש בספריה סיליקון יכול לעשות עבודה נהדרת בשיפור השימוש בדלתות הזזה הם יכולים לעזור לך למזער במידה רבה את החיכוך, כך שהדלת שלך זזה בקלות ללא בעיות.

הסרת מכשולים מרוכסי דלתות זזות

בדיקה אחר עצמים זרים

כדי לוודא שהדלת המחליפה שלך פועלת חלקה, שמור על מסילות נקיות ובדוק את הריסון והשחתה. זה אומר לחפש כל חומר זר כמו עלים, אדמה או חפצים אבודים כמו שיחי חיות מחמד. אלה יכולים לגרום למשיכת חיכוך בתוך הדלת להישחק עם הזמן. אתה עשוי לראות מה מכשולים נוספים מסתתרים במסילה מעלית שאינך רואה בעין מזומנת בעזרת פנס, מה שנותן לך את הכוח להסיר אותם גם כן. זה גם משפר את הפונקציונליות של הדלת ועוזר לדלת להימשך זמן רב יותר, מאפשר פחות ריסון ושחתה עם הזמן.

תיקון סעיפים כופרים של המסלול

ובכן, אם כלום לא שבור אתה עשוי לחשוב -תreatment-therapy but אחרת זה עשוי להיות הגורם לבעיותיך. אוהדי Crescent City מטילים על זה עין יותר חדה בקצב איטי יותר. חלקים של מסלול קשורים או ניזוקים אם המסלול ניזוק או כופף, הדלתות הגלידיות שלך עשויות שלא להפעיל בצורה חלקה. חשוב להתמודד עם בעיות אלו במהירות כדי לשמור על התפעול הנכון. התחל בבדיקה חזותית של המסלול לחיפוש כל כפיפה או הפיכת צורה. אם תבחין בהפרעות כלשהן, תוכל להשתמש בכלי להחזקה או בכלי יישור מסלול כדי להחזיר את המסלול לצורתו המקורית בזהירות. אבל אם הם נזקקו מדי, עשוי להיות זה ההכרעה הטובה ביותר להחליף אותם כדי לשמור על הדלת עובדת בצורה הטובה ביותר. זכור כי מסלול עובד נכון הוא גם מסלול בטוח ופונקציונלי.

הסדרת רכיבי שער גלישת כוח גדול

הסידור של חלקים כבדים של שער הגלידה שלך - כמו השערים והמחברות - הוא דבר חיוני לפעילות חלקה שלהם. סידור לא נכון יכול לגרום לפסי הגלגלים ולקומפוננטים אחרים של השער להיגמר מהר. בדוק את הסידור של אלו ואת החיבורי חשמל כדי לוודא שהם מאובטחים תחילה. זה מפחית את הסיכוי לתנועה לא מסודרת במהלך פעולתו, וכן מאריך את חיי המערכת. אם יש לו, יהיה צורך לבדוק אותו כי זה יכול להיות מורה טוב על סידור לא נכון אוlicted שיכולים לחסוך לך זמן וכסף בהכשרו על ידי מקצועי.

הערכה ותיקון נזק מסלול

ישרות של עקבות מתכת מעוותות

תחזוקת דלתות שולחות: מסילות מתכת מעוותות אחת מהדברים שיוכלו לגרום לבגידה וביזבוז בדלתות השולחות שלך היא מסילות מתכת מעוותות. אזורים מעוותים יכולים לגרום לדלת להיתקע, מה שגורם לה להיות פחות יעילה. השתמשו בחבטה מרוסת כדי להחזיר את החלקים הללו למצבם המקורי על ידי הכות בהם קלות חזרה לצורה. תצטרכו לבדוק עד כמה העיוות חמור, אם הוא ניתן לתקן הוא יכול להירפא, ואם לא תחליפו את חלק המסילה כדי לשמור על הקופסה שלכם בטוחה ויעילה יותר. סקרים שגרתיים יכולים לאתר את נקודות הבעיות האלו לפני שהן יהפכו לבעיה, והם ישמרו על פעולתכם והינצל לכם כסף.

החלפת קטעי מסילה שחורים

התקורוזיה היא איום גדול על שלמות ובטיחות חלקי מסלול דלתות שולחות. נדרש יש לבצע בדיקה מקיפה כדי למצוא כל ראיית תקורוזיה. עבור החלקים שיש להם קרום קורוזיה כבד, יהיה עליך למדוד אותם בדיוק ולזמין חלפים כדי להבטיח תיקון מהיר. כדי למנוע בעיות עתידיות, צבע את המסלולים החדשים בצבע מונע תקורוזיה. זה לא רק יעזור למנוע תקורוזיה נוספת אלא גם יאריך את חיי השמירה של הדלת השולחת שלך. תחזוקה סדירה והתייחסות זמנהית לקרום תקורה יכולים להאיט באופן משמעותי את חיי השמירה והיעילות של הדלת.

מתי להתחשב בהתקנת מנוע שער נע專業

למרות תחזוקה שוטפת בבית, יהיו מקרים שבהם יש צורך גדול בסיוע של מומחה, במיוחד עם בעיות הקשורים במנועי שערים אוטומטיים ושערים נדודים. אם המצב לא משתפר, כולל בעיות חשמליות חמורות יותר או החלפות חומרה הכרחיות מעבר לתחזוקה כללית, מומלץ בחום להתייעץ עם מומחה. עצה זו יכולה לעתים לחסוך הרבה זמן ולוודא שהדלת עובדת כראוי ואין סיכוי לבעיות עתידיות. קבלת סיוע בנוגע לקשיים אלו יכולה להסיר משקע מהדעת ולהשאיר אותך מרוכז על מה שאתה צריך לבצע.