The Role of Sliding Door Wheels in Effortless Movement

How Sliding Door Wheels Impact Door Functionality

Sliding door wheels are really important parts that keep doors moving smoothly and working well, making life easier for anyone who uses them. These little components actually make all the difference when it comes to how residential or commercial sliding doors function day to day. When someone opens or closes a sliding door, those wheels underneath do most of the work by cutting down on friction so everything glides along without much effort. What makes one wheel better than another? Well, it depends on things like what they're made from, their shape, and size. Bigger wheels tend to handle heavier doors better while smaller ones might struggle. According to industry folks we've talked to, spending a bit more money on good quality wheels pays off in the long run because they last longer and need less fixing over time. Getting this part right means smoother operation overall and fewer headaches down the road.

Types of Sliding Door Wheels: Nylon vs. Steel

Choosing the right sliding door wheels means understanding what sets nylon apart from steel options. Nylon wheels are light and make almost no noise when moving, which is why they work so well in homes where keeping things quiet matters. The soft glide reduces annoying sounds that might disturb people inside. On the flip side, steel wheels stand up much better to wear and tear, so they're often seen in busy places like shopping centers or office buildings. These metal wheels handle heavy doors just fine without breaking down over time. Looking at specs like how much weight they can take and how long they last shows the real difference between nylon and steel. For most folks picking out wheels, it comes down to finding the sweet spot between being quiet enough for daily living and strong enough to last through regular use.

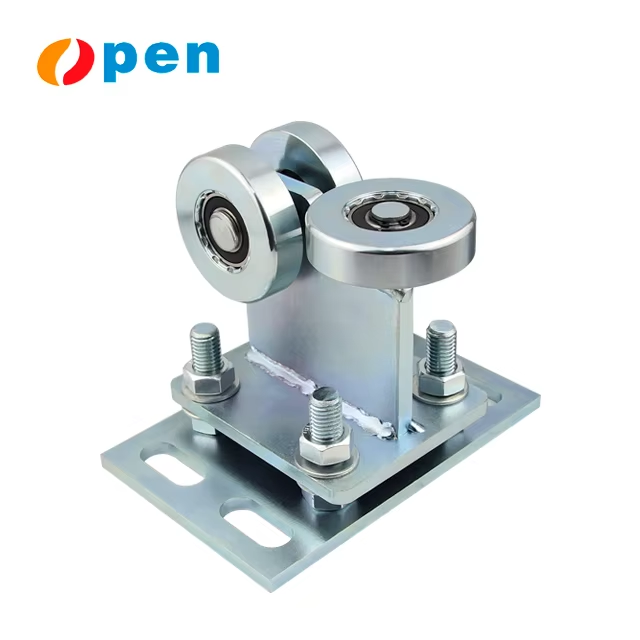

Connection Between Wheels and Automatic Sliding Gate Systems

When it comes to automatic sliding gates, those little wheels on the doors actually play a big role in how everything works. They let people push the gate manually when needed but still handle all the automated stuff powered by motors or electric openers. Good quality wheels for these systems tend to be built tougher because they have to deal with both motor strain and daily wear and tear from opening and closing repeatedly throughout the day. Most gate manufacturers will tell anyone who asks that picking the right wheels matters a lot for keeping gates running smoothly year after year. Gates with durable wheels don't need replacing as often, which saves money in the long run and keeps properties secure without unexpected breakdowns during critical moments like holidays or bad weather.

Signs Your Sliding Door Wheels Need Attention

Grinding Noises and Stiff Movement

Grinding noises while operating sliding doors usually signal that something's wrong with the wheels underneath. Most often, this happens because dirt builds up around the tracks or the wheels themselves start wearing down over time. When either of these occurs, the door doesn't glide as smoothly as it should. Some maintenance studies show friction goes up about 40% higher when there's debris buildup or worn components involved. Catching these noises before they get worse saves money on bigger fixes later on. Doors that aren't properly maintained tend to break down completely eventually, so addressing strange sounds right away keeps everything running better for longer periods between service calls.

Visible Wear on Wheel Components

When sliding door wheels show signs of wear, it's actually a red flag pointing to bigger issues down the road. The damage typically shows up as cracks, chips, or those annoying flat spots that really mess with how the door aligns and operates properly. Most technicians will tell anyone who listens that regular checks matter a lot. Looking closely at the wheels for any kind of damage isn't just good practice but necessary work. A simple visual inspection guide would go a long way toward making sure nobody skips these important checks when they should be doing them. Taking care of these problems early on saves headaches later, both in terms of money spent and time wasted dealing with broken doors after the fact.

Misalignment Caused by Damaged Wheels

When sliding door wheels get damaged, misalignment happens all the time, causing doors to stick or move unevenly which creates real safety hazards. According to what many professionals see on the job site, around one third of all sliding door problems come down to wheel misalignment, and this definitely drives up repair bills. Giving homeowners some solid troubleshooting guidance really helps catch these alignment issues early on before things get worse. Fixing them promptly keeps doors running smoothly and safely, so the whole system continues working properly without compromising home security.

Step-by-Step Guide to Wheel Maintenance

Cleaning Debris from Tracks and Wheels

Regular cleaning is crucial for maintaining the performance of sliding door wheels. Debris can accumulate in tracks and around wheels, causing excessive wear and hindering smooth operation. Here's a simple step-by-step cleaning guide:

1. Use a vacuum to remove any loose dirt and debris from the tracks.

2. Employ a soft brush to tackle stubborn areas and clean the wheels.

3. Finish with a mild detergent and lint-free cloth to wipe down both tracks and wheels.

By implementing these techniques, not only are you restoring functionality, but you're potentially extending the life of your sliding door system by up to 50%.

Lubrication Techniques for Smooth Operation

Lubricating sliding door wheels is paramount to reduce friction and prolong their lifespan. Using the right lubricant dramatically impacts performance. For best results:

1. Opt for silicone-based sprays or grease, which are suitable for most sliding door applications.

2. Apply lubricant based on door usage and environmental conditionsâtypically every 3 to 6 months.

3. Industry reports suggest that timely lubrication can decrease maintenance demands by over 30%. By adhering to these guidelines, you ensure smoother operation and save time and resources on future repairs.

Adjusting Wheel Height for Proper Alignment

Adjusting wheel height is essential for keeping doors aligned correctly with tracks and frames, preventing security gaps and ensuring smooth operation. To achieve this:

1. Follow the manufacturerâs guidelines closely, which detail specific measurements and tools required.

2. Regular adjustments during routine maintenance intervals can prevent potential alignment issues.

3. Proper alignment not only enhances operational efficiency but also helps avert future complications, securing long-term door functionality and safety.

When to Upgrade to Heavy-Duty Sliding Door Wheels

Benefits of Heavy-Duty Wheels for Large Doors

Sliding door wheels built for heavy duty work offer some pretty big advantages, particularly when dealing with large doors that get opened all day long. The main thing people notice is how these wheels stand up to serious weight and regular wear and tear, which makes doors last longer and operate smoother over time. Compared to regular wheels, heavy duty versions can take on much more stress without breaking down. This means businesses spend less money fixing things and have fewer interruptions during operation. Industry folks who actually install these wheels say they tend to stick around about three times as long as normal wheels when put through their paces daily. While the upfront cost might be higher, most companies find it pays off eventually because replacement costs drop dramatically.

Compatibility with Sliding Gate Motor Systems

Heavy duty wheels need to match up with existing sliding gate motor systems if we want them to perform at their best. Getting these components to work well together makes all the difference in day to day operations across facilities. Checking compatibility before installation helps companies dodge expensive part swaps and production stoppages that nobody wants to deal with during busy periods. Most manufacturers include detailed specs sheets that make it easier to confirm whether different parts will actually fit and function properly together. Taking the time to cross reference these details saves money in the long run while keeping gates operating smoothly without unexpected breakdowns disrupting workflow.

Installation Process for Enhanced Durability

Getting those heavy duty sliding door wheels installed right makes all the difference for keeping big doors working properly and holding up over time. When someone actually does the job right, they check wheel alignment first thing so everything runs smoothly later on, plus double checking that all bolts and brackets stay tight where they should be. Most folks find following some basic steps helps avoid headaches down the road, especially since nobody wants their doors jamming mid operation. Industry experience shows that commercial properties with properly fitted heavy duty wheels see way fewer problems during daily use, which means less downtime and repair costs in the long run. Doors just last longer too when everything gets put together correctly from day one, making sure both the door system itself and those expensive wheels perform as intended without constant maintenance issues popping up unexpectedly.