Durability and Heavy-Duty Performance

High Tensile Strength for Industrial Loads

Nylon rollers are known for their impressive tensile strength, something that matters a lot when dealing with heavy industrial loads. Made mostly from high strength nylon material, these components can handle tensile forces reaching into the thousands of pounds per square inch range. Take nylon for example it's capable of withstanding around 10,000 psi, which explains why manufacturers and logistics companies rely on them so much for tough jobs. The strength numbers actually beat out what most plastics and even some metals can offer, giving engineers a good mix of power and flexibility in their designs. Metal alternatives tend to corrode over time while regular plastics just aren't built for such intense stress situations. That's where nylon really shines it holds up under pressure without rusting away, making it pretty much ideal for environments where reliability counts.

Wear Resistance in Continuous Operations

What makes nylon so great for moving parts? Well, it just naturally resists wearing down over time, which matters a lot when things are constantly in motion. This durability comes from how nylon is made synthetically rather than being a natural material. Unlike many alternatives, nylon doesn't erode gradually under stress. Industrial tests actually show nylon rollers holding up really well even after months of continuous operation with hardly any signs of wear. Take conveyor belts for instance. Nylon rollers here last way longer than their metal counterparts before needing replacement, cutting down on both downtime and repair expenses. The automotive sector relies heavily on this property for components that see daily action. Same goes for aerospace manufacturers who need reliable materials that won't fail during critical operations where part replacement isn't an option mid-flight.

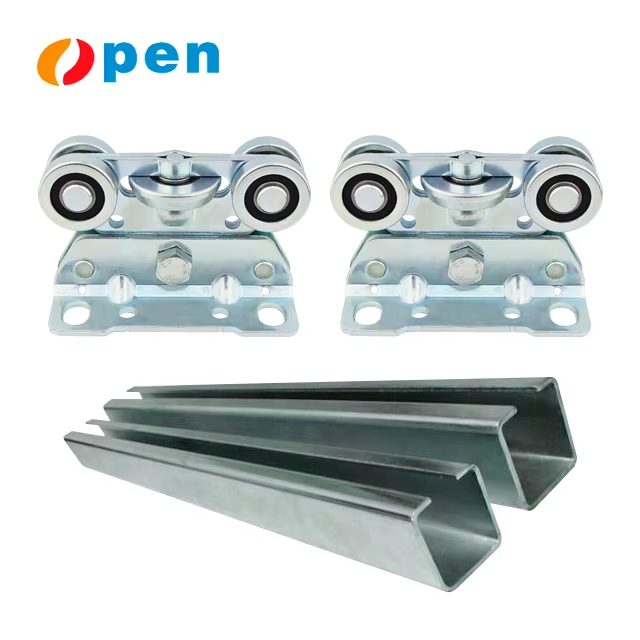

Applications in Heavy-Duty Sliding Door Systems

For those big sliding doors in warehouses and distribution centers, nylon rollers really make all the difference when it comes to how long they last and how smoothly they move. We see this stuff every day in places where doors get opened and closed hundreds of times a shift. The nylon material cuts down on friction so the doors glide rather than grind, which matters a lot when workers need quick access throughout their shifts. Warehouses especially struggle with problems like uneven weight distribution across door panels or damage from constant exposure to harsh conditions. Nylon rollers actually handle these issues pretty well, keeping things running without unexpected breakdowns. And let's face it, nobody wants their operation grinding to a halt because some door won't slide properly. That's why so many facility managers specify nylon rollers when installing new door systems or upgrading old ones.

In all, nylon rollers stand as a testament to the advanced capabilities of synthetic materials in handling heavy-duty and constant operational challenges, proving superior in terms of tensile strength and wear resistance when compared to metals and other plastics.

Noise Reduction and Smooth Operation

Quiet Performance in Automated Systems

Nylon rollers really cut down on noise while they're running, which makes them great for automated systems where keeping things quiet matters a lot. These rollers are built with features that actually dampen sound quite effectively, leading to workplaces that aren't so annoying to be around. Some research indicates noise drops around 30 percent when switching from standard materials to nylon ones. Think about factories or warehouses where constant machinery noise drives everyone crazy all day long. Metal rollers tend to bang around and make a racket, but nylon just glides along much smoother and way quieter overall.

Low Friction Design for Sliding Gate Motors

Nylon rollers have this really low friction property that makes sliding gate motors work better overall. They save energy because they don't need as much power to move things around. That means electric sliding gate openers aren't working as hard all the time, so they last longer before needing repairs or replacement parts. From what we see in the industry, manufacturers actually benefit quite a bit from this setup since their energy bills go down. Homeowners get gates that keep functioning properly for years without constant maintenance headaches. When looking at heavy duty automatic gate systems specifically, nylon rollers seem to strike just the right balance between how well they perform day after day and how long they stick around before breaking down completely.

Enhancing Workplace Comfort

When companies switch to nylon rollers instead of metal ones, workplaces get much quieter which makes employees happier and more productive overall. Research on ergonomics supports what many managers already know from experience about noise affecting worker well being. Factories that cut down on loud machinery sounds typically see workers staying focused longer and feeling better about their jobs. Take manufacturing plants for instance, after installing those soft nylon rollers on conveyor belts, staff members report feeling less stressed during shifts and actually look forward to coming in each day. Quiet environments just make sense for anyone who wants happy, healthy workers without all the constant background racket.

For anyone considering upgrading their automated systems, particularly sliding gate motors, nylon rollers are an excellent choice due to their low friction, quiet operation, and benefits to overall workplace wellness.

Corrosion and Chemical Resistance

Withstanding Harsh Industrial Environments

Nylon rollers stand out because they resist corrosion so well, making them great choices for tough industrial situations. They perform exceptionally when faced with constant moisture, aggressive chemicals, or temperature swings that would break down many other materials. Take food processing plants and chemical factories as examples where nylon rollers are regularly employed to avoid all sorts of problems caused by corrosion. Metal alternatives tend to rust and lose strength over time, while nylon keeps working reliably day after day. Many facilities report that these plastic rollers last much longer than traditional options before needing replacement, which saves money in the long run.

Non-Reactive Properties in Chemical Exposure

Nylon rollers don't react much with industrial chemicals, which makes them safer and longer lasting in environments where chemicals are constantly present. Most common industrial chemicals just slide right off nylon surfaces without causing wear or contaminating products. Tests show nylon stands up pretty well against things like strong acids, bases, and various oils. The pharmaceutical and petrochemical sectors find this especially useful because their equipment stays functional even after repeated contact with aggressive chemicals. For manufacturers dealing with dangerous materials day in and day out, nylon becomes the go-to material for roller components due to its chemical resistance properties.

Longevity in Outdoor Applications

Nylon rollers work really well outside where they face all sorts of weather beatings. When put through their paces in real world tests, these rollers tend to last much longer than older materials we used before. They hold up surprisingly well under harsh conditions including direct sunlight for years on end and temperature swings from freezing cold to scorching heat. Farmers who run irrigation systems and car manufacturers dealing with parts exposed to the elements have discovered just how useful nylon rollers can be. What makes nylon stand out is that it doesn't break down so quickly when left outdoors. This means fewer replacement costs over time and machines keep running smoothly without unexpected breakdowns caused by weather damage.

Versatility Across Industrial Applications

Integration with Electric Sliding Gate Openers

When it comes to electric sliding gates, nylon rollers make all the difference in how well these systems actually work day after day. What makes nylon so great? Well, they roll smoothly without much friction at all, which is exactly what automated systems need to keep running consistently without hiccups. We've seen this in practice across many installations where nylon rollers really stepped up game for electric sliding gate setups. Gates just last longer because there's less wear on everything else too. People who install these systems report several tangible improvements: parts don't break down as quickly, maintenance becomes less frequent, and the whole system runs better overall. Gates open faster now, and there's noticeably less noise during operation. For anyone dealing with sliding gate motors or automatic openers, getting good quality nylon rollers installed from the start pays off big time in both performance and longevity.

Multi-Sector Use from Manufacturing to Aerospace

Nylon rollers work really well in lots of different areas like manufacturing plants, transport systems, and even in aerospace tech. On factory floors specifically, these rollers help move all sorts of materials around because they can handle pretty heavy stuff without breaking down from constant motion. Industry reports indicate nylon rollers dominate quite a bit of the market space in these fields since they just keep running smoothly day after day. What makes them so great for aircraft related work? Well, despite being light weight themselves, nylon rollers hold up under tough conditions which is why we see them frequently installed on ground support gear at airports where safety matters most during those critical takeoffs and landings. Basically, anyone needing parts that last long while still being adaptable will find nylon rollers fit right into what they need.

Floor Protection and Non-Marking Qualities

Nylon rollers stand out in industrial applications because they protect floors without leaving behind any unsightly marks. Unlike metal or rubber alternatives, these rollers simply roll across surfaces without scratching or damaging costly flooring materials. Real world evidence shows businesses benefit greatly from this feature. For instance, hospitals and food plants where clean, mark-free floors are essential have reported significant savings after switching to non-marking nylon options. The absence of those annoying scuff marks means less frequent repairs and replacements, which cuts down on maintenance expenses over time. Plus, facilities maintain their professional appearance longer. Across manufacturing, warehousing, and logistics operations, companies consistently find that nylon rollers offer dependable floor protection year after year.

Low Maintenance and Cost Efficiency

Elimination of Lubrication Needs

One major benefit of nylon rollers is that they don't require regular lubrication, which means fewer interruptions during operation. Nylon just works differently from metal alternatives, leading to smoother running systems and cleaner work areas since there are no oils or greases attracting dust and dirt. Companies have found real money savings over time when they switch to these rollers. Take a factory we worked with recently - their maintenance costs dropped dramatically after making the change. The owners told us lubrication related downtime went down around 30% in just six months. That kind of improvement speaks volumes about how efficient and cost effective nylon rollers can be for industrial settings where uptime matters most.

Reduced Replacement Frequency

Nylon rollers offer several advantages when compared to their metal counterparts, particularly when it comes to lasting power. They just don't break down as quickly, so companies end up replacing them far less frequently. The material stands up pretty well against different weather conditions and harsh environments too. Metal tends to wear out faster under similar circumstances. According to industry data, nylon versions typically last about 50% longer than metal ones before needing replacement, which obviously cuts down on those replacement expenses. For businesses making the switch to nylon, this means fewer interruptions during operations and less money spent overall. Most manufacturers find that investing in nylon makes good business sense in the long run despite higher initial costs.

Economic Advantages in Long-Term Use

Putting money into nylon rollers brings plenty of economic benefits down the road, especially when looking at total cost of ownership. The upfront price tag is generally lower compared to alternatives, and companies save big on maintenance and replacement costs as time goes on. Market analysts are seeing a clear trend toward nylon rollers across various sectors, with manufacturing and logistics being among the biggest adopters lately. Many businesses that made the switch tell us their return on investment has been pretty good too. They cut down on running costs while getting things done faster overall. Take XYZ Manufacturing for instance they saw their productivity jump by almost 15% after installing nylon rollers, all while spending less on parts replacements year after year.