How Wood Properties Influence Sliding Door Wheels Performance

Density, Grain Pattern, and Surface Flatness: Key Factors Affecting Wheel Engagement

The density of wood has a big impact on how sliding door wheels handle weight distribution. Hardwoods that pack more weight per cubic foot, like oak at around 45 pounds per cubic foot, put more pressure on the rollers. This means manufacturers need to use stronger materials for the wheels, stainless steel being a good choice to prevent them from getting deformed over time. On the flip side, softer woods such as pine, which weighs approximately 25 pounds per cubic foot, work well with lighter plastic wheels without affecting performance much. The grain pattern matters too. Woods with open grains, think ash for example, tend to develop tiny cracks when subjected to constant stress. These small fractures can lead to uneven surfaces that make wheels either skip along or get stuck occasionally. To keep doors moving smoothly with minimal friction, it's important that door surfaces stay flat within about 1/16 inch for every linear foot they cover. When there are bigger dips or bumps than that, rolling resistance goes up by nearly half, which speeds up the wear and tear on both the wheels themselves and the tracks they ride on.

Solid Wood vs. Engineered/Hollow-Core Doors: Weight and Stability Implications for Sliding Door Wheels

Standard solid wood doors weighing between 70 to 100 pounds for typical 36" x 80" panels need heavy duty wheels capable of handling at least 50 pounds each, which is why many installations use four wheels together. The lighter engineered and hollow core options that weigh around 20 to 40 pounds work fine with basic systems, though they come with their own set of headaches. These doors have internal spaces that can move around when humidity levels change, causing them to warp over time and throw off roller alignment with the track system. That's why adjustable wheel housings are so important for keeping everything lined up properly. Another thing worth noting is how solid wood actually grows and shrinks across the grain by about 0.1 percent throughout seasons as temperatures and moisture levels fluctuate. Good quality door hardware should include wheel mounts with roughly 5 to 10 millimeters of extra space built in so these natural movements don't cause binding problems down the road.

Best Sliding Door Wheels Materials for Wooden Doors

Stainless Steel Sliding Door Wheels: Strength, Corrosion Resistance, and High-Load Suitability

Stainless steel wheels offer exceptional strength and last much longer than other options for those heavy wooden doors, often holding up to well over 100 pounds each. What really stands out is how they resist rusting, which makes these wheels perfect for places where moisture is always an issue. Think about bathrooms, laundry areas, or even houses near the coast where salty air hangs around. Regular carbon steel just wouldn't hold up against all that dampness and salt. Compared to wheels that are simply coated or painted, stainless steel keeps working properly for years without breaking down, especially when used with good quality track systems meant for commercial use. The American Architectural Manufacturers Association has actually set some pretty strict standards for durability in residential buildings and smaller commercial spaces, and stainless steel passes those tests with flying colors according to their AAMA 101-13 guidelines.

Nylon and Polymer Sliding Door Wheels: Quiet Operation and Vibration Absorption for Light-to-Medium Wooden Doors

Nylon and polymer wheels really shine in spaces where noise reduction is important, like bedrooms, home offices, and apartment buildings. These materials have built-in lubrication that stops the annoying rattling often found on lighter wooden doors. The result? Almost completely silent movement without needing regular oiling or adjustments. They work best on certain door types though - not so great for those heavy solid wood models. When installed correctly according to track design and weight specs, these wheels roll incredibly smoothly. Plus, since they don't conduct electricity, they help prevent static shocks inside temperature controlled environments. This actually matters more than people realize, which is why organizations like NIST include this property in their recommendations for building hardware that minimizes interference.

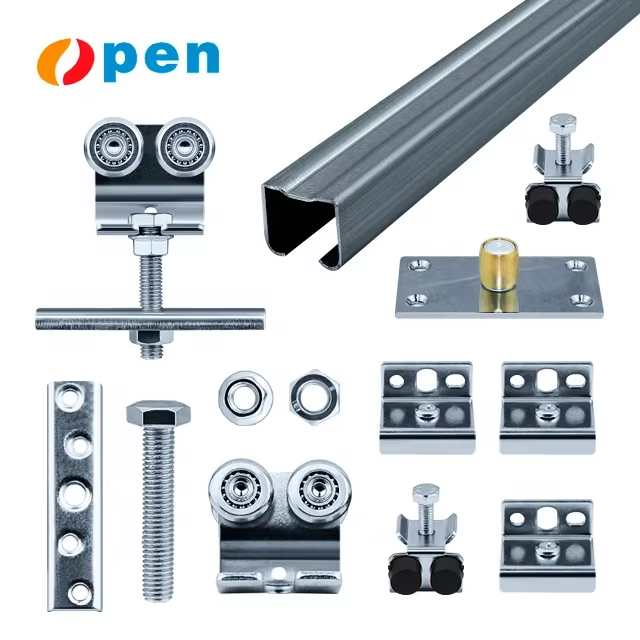

Selecting the Right Sliding Door Wheels by Load Capacity and Sizing

Calculating Total Door Weight and Distributing Load Across Multiple Sliding Door Wheels

Accurate weight assessment is foundational to wheel selection. Calculate total door weight using:

- Dimensions (height × width × thickness)

- Species-specific density (e.g., oak ≈ 45 lbs/ft³, pine ≈ 25 lbs/ft³)

- Added mass from hardware (glass inserts, handles, decorative elements)

When choosing wheels, make sure their combined dynamic load rating is at least 20% higher than what the door actually weighs. Take a 100 pound door as an example case study here. Four wheels rated for 30 pounds each would work well in practice. This isn't just about having extra capacity for safety reasons either. The real benefit comes from avoiding those situations where one wheel gets overloaded while others sit idle, which wears things out faster over time. Place pairs of wheels somewhere between six and eight inches away from each side edge of the door frame. Doors that stand taller than seven feet need something special too. Adding a third wheel right in the middle helps stop that annoying sagging effect that happens across the span. And don't forget about wheel size matching requirements based on specific applications needs.

- 40mm wheels suit lightweight doors (<150 lbs)

- 60mm wheels handle medium loads (150–400 lbs)

- 80mm+ wheels support heavy solid-wood doors and commercial installations

Undersized wheels increase friction by up to 70%, hastening track degradation and reducing system lifespan.

Installation and Maintenance Best Practices to Sustain Smooth Movement

Getting installation right from day one and keeping up with regular maintenance makes all the difference for lasting performance. Start by checking track alignment with a laser level because even something as small as 1/32 inch off can lead to serious problems down the road like binding issues and bearings wearing out way too fast. Mount those plates straight into the actual framing members like studs or metal rails instead of just nailing them to drywall or other surface materials. This helps handle the movement and forces these systems experience daily without compromising safety. When it comes to wheel placement, follow what the manufacturer recommends usually around 12 to 18 inches from each side. Proper spacing keeps weight distributed evenly across the entire system and stops that annoying twisting effect that happens when doors get misaligned over time.

Check things out four times a year at least. Grab a dry brush and sweep away any dirt or grime stuck in the tracks before it turns into something that can scratch surfaces over time. When it comes to lubricating those bearings, stick with silicone sprays only please. The petroleum stuff might seem similar but it actually draws in dust particles and makes everything wear down faster. Every month or so, take a listen while running through operations. If there's any kind of scraping noise or strange clicks happening, that usually means parts are getting out of alignment or simply worn out. As for replacing wheels, nylon ones typically need swapping around every three to five years give or take. Stainless steel lasts longer obviously, maybe seven to ten years depending on how much they get used daily and what kind of environment they're sitting in. Stick with this routine and most folks find their equipment runs smoother with about 40% less friction compared to standard setups, plus components tend to last way past what manufacturers typically guarantee.

FAQs

What factors influence sliding door wheels performance?

The main factors include wood density, grain pattern, and surface flatness. Dense woods require strong materials like stainless steel for wheels, while grain patterns can cause tiny fractures that affect wheel movement.

How does wheel installation impact performance?

Proper installation, including track alignment and correct wheel placement, ensures even weight distribution and reduces wear and tear. Regular maintenance like cleaning tracks and lubricating bearings is crucial for smooth operation.

Why choose stainless steel wheels for wooden doors?

Stainless steel wheels offer strength, corrosion resistance, and handle high loads, making them ideal for heavy wooden doors exposed to moisture.