Superior Durability and Weather Resistance of Nylon Rollers

UV Stability and Cold-Weather Performance: Nylon 66 vs. Acetal

When it comes to extreme outdoor conditions, Nylon 66 rollers beat acetal hands down. They hold their shape even at freezing temperatures as low as minus 40 degrees Fahrenheit and stand up to sunlight without needing any special additives. The material's unique makeup stops problems like cracks, warping, and loss of strength over time when exposed to the sun something acetal just can't handle. Acetal tends to get brittle when it gets really cold and breaks down much faster under constant UV exposure. This makes Nylon 66 the go to choice for cantilever gates installed in places with heavy snowfall or mountainous areas where gates made from acetal often stop working properly after only two or three winters. Plus, Nylon 66 doesn't expand and contract so much with temperature changes, which means fewer alignment issues and jammed gates during operation.

Corrosion-Free Operation in Coastal and High-Humidity Environments

Nylon rollers stop those annoying rust problems that happen so often in places with lots of salt in the air or high humidity. This really matters for coastal homes and factories near the sea, since salt particles floating around can wear down metals up to four times faster than what happens inland. Steel rollers need all sorts of protective coatings applied regularly or they just have to be replaced constantly. But nylon is different because it's not metal at all, so it naturally stands up against chlorides and stays strong even when completely surrounded by moisture without developing pits or corroding from contact with other metals. Nylon also doesn't soak up water thanks to its water-repelling properties, which gives it a big edge over materials like wood that absorb moisture easily or some composite materials that aren't as dense. Maintenance becomes way cheaper with nylon rollers too. No need for special chemicals to treat them, no rust prevention stuff, and definitely no regular checkups during seasons when things get worse. We've seen these nylon rollers last for years on end in harsh marine conditions or areas exposed to industrial chemical spills without showing any signs of wear.

Optimized Load Handling and Low-Friction Performance

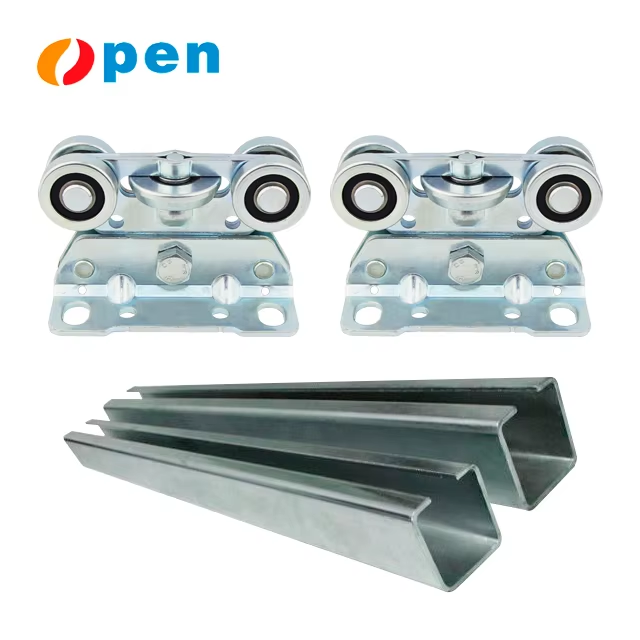

Static Load Capacity: Supporting 8-16 ft Cantilever Gates (1,200-2,500 lb Rating)

Nylon rollers can handle radial loads of around 2,500 pounds, making them good enough for those big commercial cantilever gates that stretch across 16 feet or so. What gives nylon this strength is basically its tight molecular structure plus pretty decent impact resistance that stops it from warping when pressure builds up over time. Compared to stiff metal options, nylon actually bends just enough to soak up those sudden jolts when gates swing open or close suddenly. Tests done by polymer engineers show this flexibility cuts down on structural stress by roughly 30%, which matters a lot for long term durability in real world applications.

Friction Reduction: Nylon’s 0.15 Coefficient vs. Steel-on-Steel (0.58)

The natural slipperiness of nylon gives it a friction coefficient around 0.15 which is actually four times better than when steel rubs against steel at 0.58. What does this mean practically? Well, machines need about 40% less power to operate, so they consume far less energy overall. When there's less friction happening, components don't get as hot during those long running operations either. No need for extra lubricants since the material basically takes care of itself. Components last longer too because there's not so much grinding going on between parts. Tribology experts have looked into this stuff recently and found that nylon keeps performing consistently even after tens of thousands of operation cycles without breaking down or losing effectiveness.

Simplified Installation and Minimal Maintenance for Commercial Use

Tool-Free Adjustment and Self-Aligning Mounting Cuts Labor Time by 40%

The nylon rollers make installation much easier thanks to their built-in adjustments that don't need tools and mounts that find the right angle all on their own. This eliminates those frustrating calibration mistakes people often make when setting things up manually and cuts down labor time by around 40% compared to older systems. Made from a special polymer material that resists friction and won't corrode, these rollers stay clean even in places where lots of foot traffic creates dirt buildup problems. The stuff lasts through all kinds of weather conditions too, so there's no need to constantly adjust or service them like steel versions require every season change.

Long-Term Cost Efficiency and Total Ownership Value

ROI Over 10 Years: Fewer Replacements + Zero Lubrication Costs

Switching to nylon rollers can cut down on long term expenses for cantilever gates because they eliminate those ongoing lubrication costs that typically run around $200 each year per gate. Plus, these rollers last much longer too, needing replacement only 30 to 40 percent of what steel ones would require over ten years. That means gate owners save between $1,500 and $2,000 on parts and labor for each unit installed. And when we factor in their ability to withstand UV damage and resist corrosion, nylon rollers deliver roughly 40 to 50 percent savings in total cost compared to traditional steel options. Most gate operators see their investment pay off within just three years thanks to not having to spend money on regular lubrication and being able to extend maintenance schedules. The money saved keeps adding up throughout the entire lifespan of the system, which is particularly important in factories and warehouses where every hour lost to maintenance affects both production output and bottom line expenses.

FAQ

Why is Nylon 66 more durable in cold weather compared to Acetal?

Nylon 66 maintains its structural integrity and flexibility even at temperatures as low as minus 40 degrees Fahrenheit, whereas Acetal becomes brittle and breaks down faster under such conditions.

How does Nylon resist corrosion in coastal environments?

Nylon resists corrosion naturally as it is not a metal; it stands strong against chlorides without developing pits or reacting with moisture which is prevalent in coastal areas.

What is the friction coefficient of Nylon compared to steel?

Nylon has a lower friction coefficient of 0.15 compared to steel-on-steel, which is 0.58, reducing the energy consumption and wear and tear on components.

How does switching to Nylon rollers affect long-term costs?

Nylon rollers reduce long-term costs by eliminating lubrication expenses, requiring fewer replacements, and delivering significant savings in total ownership value over ten years.