슬라이딩 도어 롤러의 이해: 기능, 중요성 및 영향

슬라이딩 도어 롤러가 원활하고 조용한 작동을 가능하게 하는 방법

슬라이딩 도어 롤러는 나일론 또는 강화 스틸과 같은 특수 설계된 베어링과 재료 덕분에 마찰력을 크게 줄여줍니다. 이러한 롤러들이 도어의 무게를 전체 트랙에 고르게 분산시킴으로써 사용자의 노력 없이도 도어가 부드럽게 움직입니다. 하드웨어 연구소에서 작년에 실시한 테스트에 따르면, 고품질 모델의 경우 도어 개폐를 약 40% 더 쉽게 만들어 줍니다. 소음 문제 또한 상당히 잘 해결됩니다. 대부분의 현대식 롤러 시스템은 폴리머 코팅과 밀폐형 볼 베어링을 갖추고 있어 성가신 진동을 흡수합니다. 약 250파운드 정도의 상당한 무게를 지닌 상태에서도 이러한 부품이 장착된 도어는 거의 무음에 가깝게 작동합니다.

무게 분배, 정렬 및 장기적인 구조 보호

정렬이 잘 된 롤러는 도어 처짐의 주요 원인인 트랙과 프레임에 가해지는 불균형한 하중을 방지합니다. 트랙 벽으로부터 2~3mm의 간격을 유지하면 알루미늄 프레임의 휨을 유발할 수 있는 좌우 흔들림을 제거할 수 있습니다. 표준화된 하중 분산 절차를 따르는 상업용 설치 시스템은 정렬이 잘못된 시스템 대비 5년 동안 구조적 수리 건수가 75% 적게 발생합니다.

왜 적시 유지보수가 트랙 및 프레임 손상을 예방하는가

실리콘 기반 스프레이로 연 1회 청소 및 윤활을 실시하면 롤러 마모를 60% 감소시킬 수 있습니다(Hardware Maintenance Institute, 2023). 관리되지 않은 롤러는 트랙과 마찰되며 하중 지지 능력을 저하시키는 홈을 형성하게 됩니다. 손상된 트랙 교체 비용은 사전 예방적 유지보수 비용보다 3~5배 더 들며, 평균 수리 비용은 380달러를 초과합니다.

간과되기 쉬운 부품의 역설: 작은 부품, 큰 결과

문 시스템 전체 비용의 단지 0.5%만을 차지하지만, 2023년 상업용 도어 분석에 따르면 고장난 롤러가 긴급 서비스 요청의 68%를 차지한다. 이러한 롤러의 열화는 트랙 휨, 밀봉 손상 및 유리 패널의 응력 파열까지 초래하며, 소규모 부품이 전체 시스템에 비례 이상의 영향을 미칠 수 있음을 보여준다.

슬라이딩 도어 롤러 교체 시기 인식하기

롤러 마모의 일반적인 징후: 걸림, 삐걱거림, 끌림 및 정렬 불일치

지속적인 마찰은 대개 마모된 롤러를 나타낸다. 주요 징후로는 다음이 있다:

- 움직임 중 걸리거나 머뭇거림

- 고주파 삐걱거리는 소리 또는 긁히는 소음 (2023년 조사에서 응답한 주택 소유자의 62%가 최초 경고 신호로 보고함)

- 가시성 처짐 또는 정렬 불량 트랙 중심선에서 1/8인치(3mm) 이상 벗어남

- 불규칙한 끌기 트랙에 긁힘 자국을 남김

2023년 재료 피로 연구에 따르면, 80파운드(36kg)를 초과하는 문을 지지하는 롤러는 더 가벼운 하중을 다루는 롤러보다 42% 더 빠르게 열화됨

롤러 성능 및 기능을 평가하기 위한 간단한 DIY 점검 방법

이 점검을 반기별로 수행하세요:

- 수직 흔들림 테스트 : 문을 약간 들어 올리세요. 1/4인치(6mm) 이상 올라간다면 롤러가 하중을 충분히 지지하지 못하고 있는 것입니다.

- 롤러 회전 테스트 : 롤러를 수동으로 돌려보세요. 딱딱하거나 끊기는 움직임은 베어링 고착을 나타냅니다.

- 트랙 정렬 점검 : 직선 자를 사용하십시오. 1/16인치(1.5mm)보다 큰 틈은 수정이 필요합니다.

상업용 등급의 롤러가 장착된 도어는 사용 빈도가 높기 때문에 분기별로 이러한 점검을 수행해야 합니다.

문제 해결 가이드: 롤러 문제와 트랙 또는 하드웨어 문제 구분하기

| 증상 | 롤러 원인 | 트랙/하드웨어 원인 |

|---|---|---|

| 특정 지점에서 걸림 | 플랫 스팟이 생긴 롤러 | 트랙 채널 내 이물질 |

| 전체 도어 저항 | 고착된 베어링 | 열팽창으로 인한 레일의 휨 현상 |

| 간헐적인 충격음 | 파손된 롤러 마운트 | 레일 고정 부속품의 느슨함 |

레일에서 문을 들어 올렸을 때(안전을 위해 목재 쐐기를 사용) 문이 부드럽게 움직인다면, 문제는 대부분 롤러에 있는 것입니다. 교체 후에도 지속되는 문제는 일반적으로 레일 손상이나 구조적 침하를 의미하며 전문가의 점검이 필요합니다.

슬라이딩 도어 롤러의 종류와 재질: 최적의 선택을 위한 가이드

바닥 롤러식과 상부 행잉식 시스템 비교: 차이점과 각각의 장점

현재 슬라이딩 도어 롤러는 기본적으로 두 가지 방식으로 작동합니다: 하부 구동 방식과 상부 걸이 방식입니다. 하부 구동 구조의 경우, 문의 전체 무게가 아래쪽 바퀴에 집중됩니다. 따라서 무거운 유리 패널이나 추가적인 안정성이 필요한 고체 금속 도어에 적합합니다. 반면, 상부 걸이 시스템은 천장 근처에 설치된 상단 트랙을 통해 도어를 위에서 들어 올립니다. 이 방식은 바닥 수준의 마모를 줄여주며 기존 방식에 비해 약 34% 정도 더 적은 실내 높이(헤드룸)만 필요로 합니다. 대부분의 사람들은 주택 내부의 가벼운 문에 이 유형을 선호합니다. 한편, 하부 장착형 롤러는 폭풍이나 혹한의 날씨에서도 좌우 안정성이 훨씬 우수하여 강한 바람에도 더 잘 견딥니다.

나일론, 스틸, 브라스 롤러 비교: 내구성, 소음, 비용 분석

사용하는 재료는 제품의 성능에서 큰 차이를 만듭니다. 예를 들어 나일론 롤러는 거의 무소음으로 작동하며 쉽게 부식되지 않지만, 중량 하중을 다룰 때 강철보다 약 40퍼센트 정도 더 빨리 마모되는 경향이 있습니다. 강철 제품은 확실히 더 오래 사용할 수 있지만, 진동을 시스템 전체로 전달하는 문제점이 있으며 특히 습한 지역에서는 정기적인 윤활이 필요합니다. 또 다른 선택지인 황동은 자연스럽게 녹에 잘 견디지만, 나일론보다 비용이 약 2.5배 정도 더 듭니다. 최근 소비자 동향을 살펴보면, 홈하드웨어가 2023년 실시한 설문조사에 따르면 응답한 주택 소유자의 거의 70퍼센트가 조용한 작동과 평균적으로 한 쌍당 약 12달러라는 합리적인 가격, 그리고 현재 시장에 나와 있는 거의 모든 종류의 트랙 시스템과 호환된다는 이유로 자택에 나일론 제품을 선택했습니다.

도어 모델에 맞는 올바른 크기와 하중 등급 선택하기

적정 하중 용량을 정확히 설정하는 것이 매우 중요합니다. 실제로 발생하는 조기 롤러 고장의 약 70%는 부적절한 하중 등급이 원인이기 때문입니다. 무엇보다 먼저 문의 무게를 정확히 파악하세요. 일반적인 실내 도어 대부분은 80~120파운드(약 36~54kg) 사이이지만, 무거운 유리 슬라이딩 도어는 종종 200파운드(약 91kg)를 초과하기도 합니다. 롤러를 선택할 때는 실제 문 무게보다 최소 15~20% 이상 높은 하중 등급을 선택하는 것이 안전합니다. 또한 롤러의 지름과 샤프트 너비를 꼼꼼하게 측정하는 것을 잊지 마세요. 믿기 어려우시겠지만, 지름이나 샤프트 너비에서 겨우 1/16인치(약 1.6mm) 정도의 오차만 있어도 향후 전체적인 정렬에 문제가 생길 수 있습니다.

데이터 인사이트: 홈오너의 68%는 균형 잡힌 성능을 위해 나일론 롤러를 선호함

나일론은 진동 완충 특성과 다양한 트랙 호환성 덕분에 주거용 시장을 주도하고 있습니다. 강철은 산업용 응용 분야에서 여전히 필수적이지만, 가정용 사용자들이 조용한 작동을 요구함에 따라 나일론의 매출은 2021년 이후 연간 22% 성장했습니다.

슬라이딩 도어 롤러 교체: 단계별 안내서

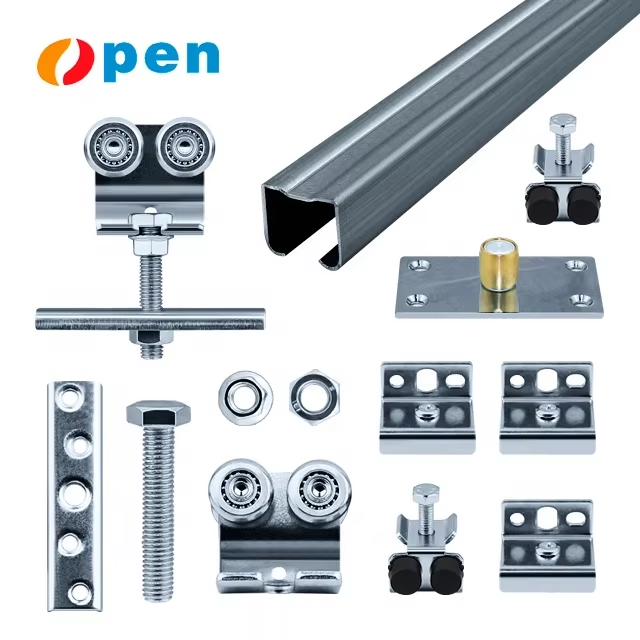

롤러 교체에 필요한 도구 및 자재

가변 렌치, 십자 드라이버, 니퍼 플라이어 및 안전 장갑을 준비하세요. 문의 무게에 맞는 교체용 롤러(일반적으로 100~250파운드)와 실리콘 기반 윤활제를 함께 준비하십시오. 범용 롤러는 대부분의 시스템에 적합하지만, 300파운드 이상의 패널을 교체할 경우 제조사 매뉴얼을 참조하여 OEM 사양을 확인하십시오.

롤러 접근을 위한 슬라이딩 도어 패널의 안전한 분리

도움을 받아 문을 수직으로 들어 올려 상단 트랙에서 분리한 후 하단을 바깥쪽으로 기울이세요. 긁힘을 방지하기 위해 패딩된 톱각대 위에 올려놓으십시오. 분해 중 날카로운 모서리로부터 손을 보호하기 위해 장갑을 착용하세요.

최적의 맞춤성과 기능을 위해 새로운 롤러 설치 및 조정

- 교체용 롤러를 마운팅 브래킷에 정렬하고 나사 구멍이 일치하는지 확인

- 롤러가 트랙에 약간 닿을 때까지 나사를 조임

- 수평 이동을 테스트하고 롤러의 장력 나사를 이용해 부드럽고 마찰 없는 작동이 될 때까지 높이를 조정

설치 중 일반적인 실수 피하기

- 나사를 과도하게 조이는 것 , 이는 브래킷의 변형을 유발하고 트랙 마모를 가속화함

- 부적합한 하중 등급 , 이로 인해 항력이 42% 증가함 (Window Safety Institute, 2022)

- 트랙 내 이물질 무시 , 이는 마모와 조기 고장을 유발함

OEM과 범용 롤러: 장점, 단점 및 호환성 고려 사항

| 인자 | OEM 롤러 | 범용 롤러 |

|---|---|---|

| 비용 | 25–40% 더 높음 | 세트당 8~15달러 |

| 호환성 | 정확한 맞춤 보장 | 샘이 필요할 수 있음 |

| 내구성 | 8~12년 수명 | 5~7년 수명 |

무거운(300파운드 초과) 또는 특수 도어에는 OEM 롤러를 선택하세요. 범용 옵션은 트랙 프로필과 홈 깊이가 일치하는 경우 표준 주거용 시스템에 잘 작동합니다.

수명 연장과 원활한 작동을 위한 슬라이딩 도어 롤러 유지 관리

레일 및 롤러 청소를 위한 효과적인 기술

좋은 주간 관습은 먼저 경로 주변에서 접근하기 어려운 곳을 균열 도구로 진공 청소하는 것부터 시작합니다. 그 다음 마이크로 섬유 가루 를 들고 가볍게 비누 용액 을 넣어 부드럽게 게 해 주세요. 정말 단단한 흙이 쌓인다면, 베이킹 소다와 물로 페이스트를 만들려고 노력하세요. 이 혼합물 을 10분에서 15분 정도 표면에 얹어 두면, 나일론 붓으로 잘 닦으면 기적이 된다. 롤러 자체를 위해, 70%의 마신 알코올을 얻으십시오. 딱딱한 잔류를 잘 처리합니다. 잘 다루지 않으면 문제가 될 수 있는 밀폐를 망치지 않고요.

기후별 최적의 윤활제 및 권장 적용 빈도

실리콘계 윤활제는 2023년 슬라이딩 시스템 테스트 결과에 따르면 석유계 제품 대비 마찰을 43% 감소시킵니다. 적용 주기는 다음과 같습니다:

- 3개월 해안 지역 또는 습한 지역 (염분 부식 방지를 위해)

- 6개월 건조한 기후 지역

- 월간 상업용 또는 고강도 사용 주거용 도어에 적합

먼지를 유발할 수 있는 에어로졸 스프레이 대신 정밀 도포기 병을 사용하여 베어링과 트랙 홈에 정확하게 도포하고 먼지 흡착을 방지하십시오.

롤러 수명 연장 및 문제 예방을 위한 정기 유지보수 팁

다음 항목에 대해 반기별 점검을 실시하십시오:

- 트레드 마모 불균형

- 롤러 하우징의 금속 피로

- 트랙 평탄도 (수직 및 수평으로 레벨기를 배치하여 점검)

2023년 전국 하드웨어 보고서에 따르면 조기 롤러 고장의 72%가 부적절한 청소 용품 사용에서 비롯되었다. 나일론 및 스테인리스 스틸 부품을 보호하기 위해 항상 pH 중성 청소제를 사용해야 한다.

자주 묻는 질문

슬라이딩 도어 롤러가 마모되는 원인은 무엇입니까?

슬라이딩 도어 롤러는 시간이 지남에 따라 마찰과 무게 하중으로 인해 마모되며, 특히 유지보수가 소홀할 경우 더욱 심해집니다. 무거운 도어나 부적절한 설치 또한 마모를 가속화할 수 있습니다.

슬라이딩 도어 롤러는 얼마나 자주 윤활유를 발라야 하나요?

습한 기후에서는 3개월마다, 건조한 기후에서는 6개월마다 윤활유를 발라면 충분합니다. 사용 빈도가 높은 지역의 경우 매월 윤활유를 바르는 것이 좋습니다.

슬라이딩 도어 롤러를 직접 교체할 수 있나요?

예, 적절한 도구와 주의 깊은 설명서 확인만 있다면 많은 주택 소유자들이 직접 슬라이딩 도어 롤러를 성공적으로 교체하고 있습니다.

나일론 롤러와 강철 롤러의 차이점은 무엇인가요?

나일론 롤러는 소음이 적고 부식에 강한 반면, 강철 롤러는 더 튼튼하지만 진동을 전달할 수 있습니다. 황동 롤러는 녹에 강하지만 비용이 더 많이 듭니다.