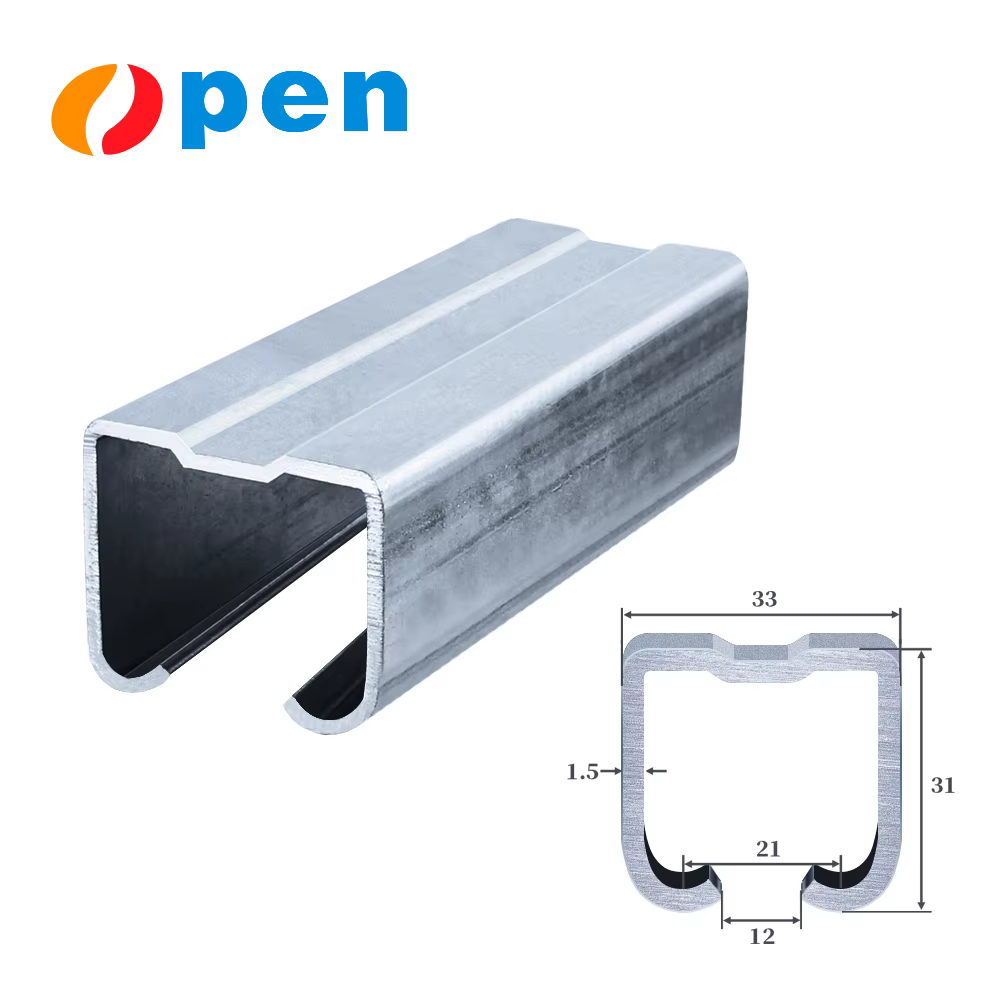

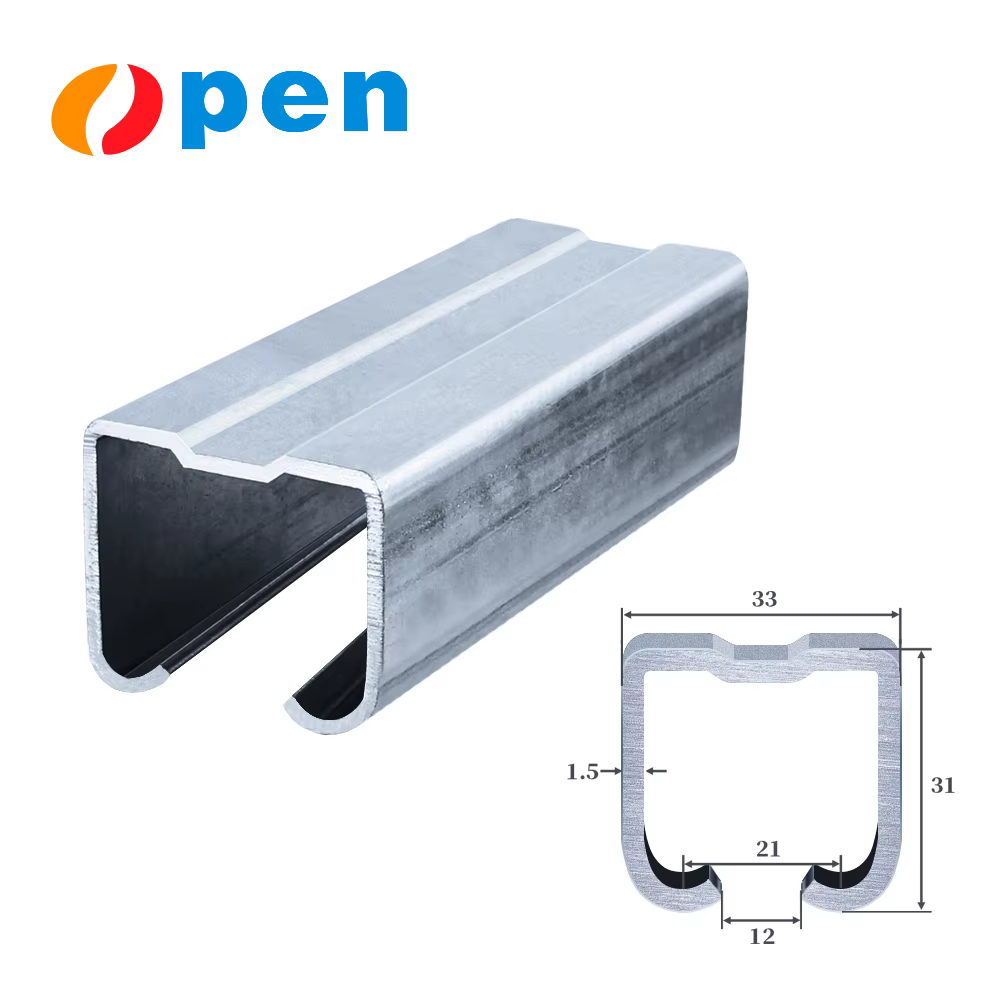

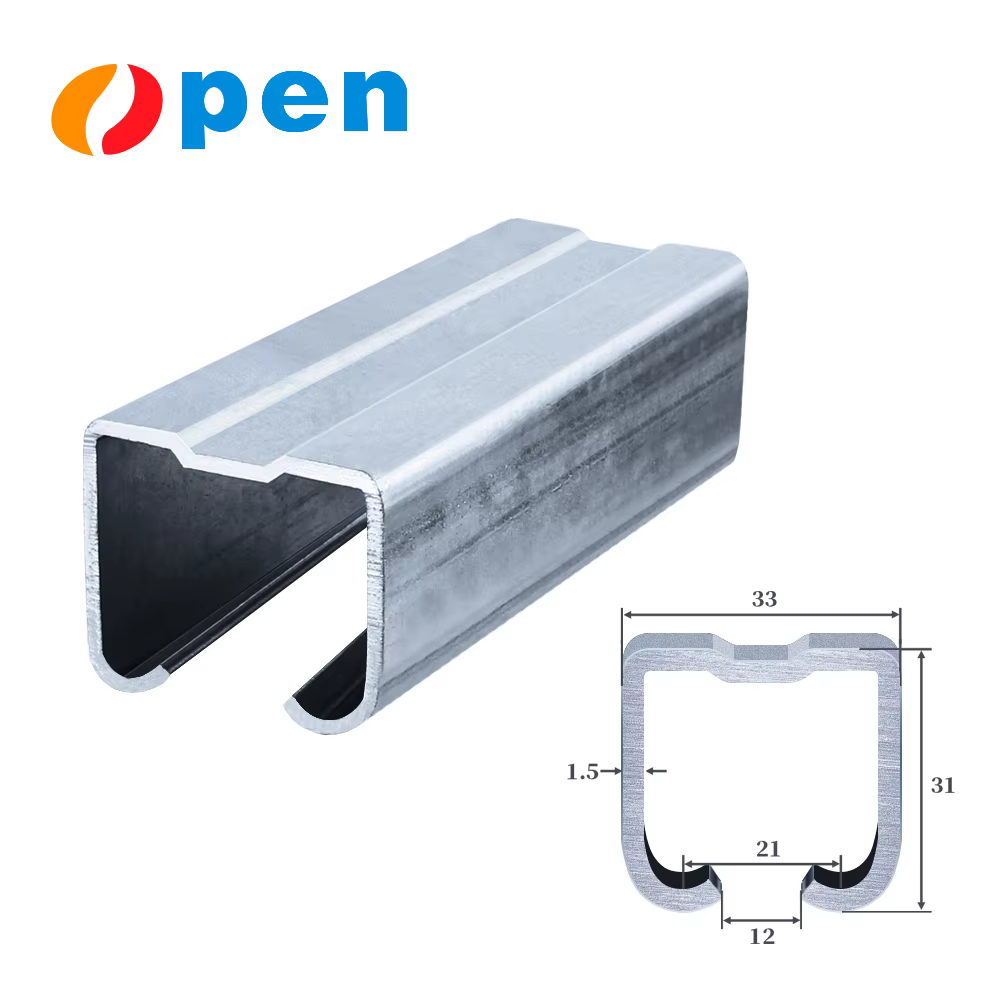

Warehouses require heavy duty sliding door rollers that can withstand the demanding conditions of daily operation, including frequent use, heavy doors, and exposure to dust, debris, and varying temperatures. Zhejiang Oupeng Electromechanical Technology Co., Ltd. offers heavy duty sliding door rollers for warehouse applications, designed to meet the specific needs of these industrial environments. Warehouse sliding doors are often large and heavy, made from materials like steel to provide security and insulation. Our heavy-duty rollers are built to support the substantial weight of these doors, with load-bearing capacities that exceed standard rollers. They are constructed from durable materials, such as heat-treated steel and high-performance nylon, which can withstand the stress of continuous use and resist damage from impact or heavy loads. The warehouse environment is often dusty and may have debris on the floor, which can affect roller performance. Our rollers are designed with features that prevent the accumulation of dust and debris, such as sealed bearings that keep contaminants out and ensure smooth operation. This reduces the need for frequent cleaning and maintenance, minimizing downtime in the warehouse. The rollers are also engineered to operate smoothly even in temperature fluctuations, which are common in warehouses that are not climate-controlled. They can withstand both high and low temperatures without losing their performance characteristics, ensuring reliable operation throughout the year. We offer a range of heavy duty sliding door rollers for warehouse doors in different sizes and configurations to fit various door types, including overhead sliding doors, sliding partition doors, and loading dock doors. The rollers are compatible with most standard warehouse door rails, making installation and replacement easy. Our technical team can also provide advice on selecting the right rollers for your specific warehouse door, taking into account factors such as door weight, frequency of use, and environmental conditions. Each roller undergoes strict quality testing to ensure it meets the demands of warehouse use, including tests for durability, load capacity, and resistance to wear. With our heavy duty sliding door rollers for warehouse, you can ensure that your warehouse doors operate efficiently, reducing the risk of breakdowns and keeping your operations running smoothly.