Material and Bearing Design: Core Drivers of Hanger Roller Stability

Nylon vs. Steel Rollers: Trade-offs in Friction, Noise, and Load Retention

What materials we pick really affects how well hanger rollers perform when it comes to friction levels, noise production, and what kind of weight they can handle. Nylon rollers create about half to two thirds less kinetic friction compared to steel counterparts. This means they run much smoother and quieter too, often needing little or no lubrication at all during normal operation. Because nylon has these special viscoelastic qualities, it actually soaks up vibrations pretty well, cutting down on operational noise somewhere around 15 to maybe even 20 decibels. That makes nylon rollers great choices for places like homes or hotels where quietness matters most. Steel rollers tell a different story though. They hold their shape much better when subjected to heavy weights above 200 pounds, something nylon just can't match long term without showing signs of deformation. While steel isn't as good against rust as nylon is, it stands up far better to heat changes in factory settings. So when deciding between these options, think about what matters most for the job at hand. Go with nylon if keeping things quiet and handling average loads is priority number one. Steel becomes the go to material whenever maximum load capacity and maintaining dimensions over years of use become absolutely essential.

Ball Bearing Precision: How Bearing Tolerance and Preload Minimize Wobble and Track Deviation

The foundation of stability starts right at the bearing level itself. Modern high precision ball bearings can actually reach those incredibly tight radial tolerances around plus or minus 0.0005 inches, and they come with this calibrated axial preload feature that basically eliminates any internal play within the system. When we talk about tighter tolerances, what happens is the wobble gets reduced by roughly 70 percent, which makes a huge difference. At the same time, that preload factor boosts overall system stiffness so the roller stays nicely centered inside its track when things are moving dynamically. This combination works wonders for keeping track deviations under control, typically staying well below that 0.5 mm per meter threshold. Plus, it helps distribute loads evenly across all those rolling components. The end result? Less wear and tear on everything involved, better preservation of track geometry, and doors that keep operating consistently through tens of thousands of cycles without needing constant readjustments or part replacements down the line.

Load Capacity Alignment: Matching Hanger Roller Ratings to Real-World Door Dynamics

Calculating Effective Load: Static Weight + Dynamic Forces from Opening/Closing Cycles

When assessing loads, we need to look past just the static weight numbers. Take a typical 200 pound door as an example it actually creates forces between 260 and 280 pounds when slamming shut quickly because of all the moving parts, acceleration happening, plus vibrations throughout the structure. Most industry guidelines like ANSI/BHMA A156.19 suggest factoring in around 30 to 40 percent extra for these dynamic forces when picking out hanger rollers. Failing to account for this total load causes problems down the road premature wear on components, things getting out of alignment, and eventually complete system failures that affect everything from the rollers themselves right through to the whole hanging mechanism. Good quality rollers that are properly sized maintain their alignment much better and keep working as intended even during regular daily use rather than only performing well under controlled testing environments.

The Over-Specification Risk: How Excess Capacity Can Accelerate Track Wear and Reduce Stability

When hanger rollers are oversized, there are actually hidden costs involved. Roller units that have twice the needed capacity tend to put extra pressure on track surfaces somewhere around 18 to maybe even 22 percent. This causes grooves to deform faster and makes contact between parts less uniform. What happens next is pretty interesting - when there's this size mismatch, it creates some sideways movement which leads to noticeable wobbling, even if the roller itself hasn't broken down at all. A recent study from the Ponemon Institute back in 2023 found that places where people install these overrated rollers end up spending about 37% more money fixing tracks after just five years. Getting the right specs means finding that sweet spot between safety requirements and how well everything fits together mechanically. Basically, we need enough power to deal with moving loads but not so much that it starts messing with how tracks engage or creates unwanted shaking problems down the road.

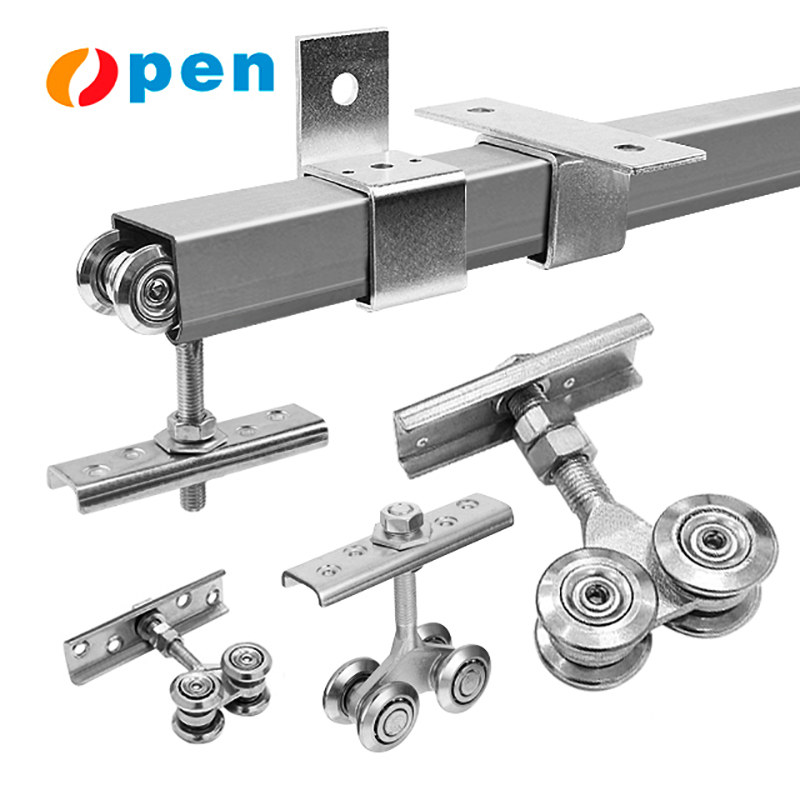

Dimensional Compatibility: Ensuring Hanger Roller Fit Prevents Binding and Misalignment

Key Metrics—Diameter, Stem Length, and Axle Clearance—for Seamless Track Engagement

The smooth operation of tracks depends on three key measurements: roller diameter, stem length, and axle clearance. The roller needs to fit snugly into the track groove, ideally matching within plus or minus half a millimeter. If it's too big, things get stuck. Too small? The whole system becomes unstable side to side. Stem length affects how the suspension works vertically. When this measurement falls short, gaps form between components which makes everything wobble more and puts uneven pressure on different parts. Axle clearance usually sits somewhere between 0.1 and 0.3 mm. There needs to be enough space for parts to turn freely, but not so much that they start moving around destructively. Studies show when any dimension strays beyond 0.2 mm from specs, rollers need replacing about 40% more often because stress gets distributed unevenly across the track surface, causing faster wear. Checking these three numbers at installation time isn't just good practice—it's necessary to avoid gradual damage buildup and keep doors operating smoothly over years instead of months.

Installation Precision: How Proper Hanger Roller Alignment Secures Long-Term Stability

Tolerance Stack-Up in Multi-Roller Systems: Why Sub-Millimeter Errors Compound Instability

When working with multi roller systems, particularly those with four point suspension doors, small alignment mistakes tend to build up across the whole system. What might look like just a tiny 0.3mm error on each roller actually adds up to around 2mm of total misalignment throughout the system. According to research from Industrial Mechanics Journal back in 2023, this kind of cumulative error leads to about 18% more friction and wears down specific sections of the track much faster than normal. The result? Binding issues, erratic movement patterns, unequal weight distribution between rollers, and ultimately early failure of components. If these little mistakes aren't fixed during setup, they can cut the entire system's useful life short by as much as 40%. Proper alignment checks at installation time aren't something that can be skipped over. Using laser guidance equipment or high precision leveling instruments isn't just good practice, it's absolutely essential for maintaining structural stability, ensuring smooth running operation, and getting the most out of maintenance schedules.

FAQ Section

Q: What materials are commonly used for hanger rollers?

A: Nylon and steel are commonly used materials for hanger rollers, each offering different benefits regarding friction, noise level, and load capacity.

Q: Why is precision in ball bearings important for roller systems?

A: Precision in ball bearings ensures minimized wobble and track deviation, positively affecting the stability and lifespan of hanger roller systems.

Q: How does over-specification affect the track wear?

A: Over-specification leads to accelerated track wear and reduced stability, as oversized rollers exert excess pressure on track surfaces.

Q: Which dimensions are critical for ensuring dimensional compatibility?

A: Key dimensions for dimensional compatibility include roller diameter, stem length, and axle clearance, which ensure seamless track engagement.

Q: How do alignment errors affect multi-roller systems?

A: Alignment errors in multi-roller systems lead to compounded instability, resulting in increased friction and accelerated wear on specific track sections.

Table of Contents

- Material and Bearing Design: Core Drivers of Hanger Roller Stability

- Load Capacity Alignment: Matching Hanger Roller Ratings to Real-World Door Dynamics

- Dimensional Compatibility: Ensuring Hanger Roller Fit Prevents Binding and Misalignment

- Installation Precision: How Proper Hanger Roller Alignment Secures Long-Term Stability