What Is a Gate Roller and How Does It Work?

Definition and Basic Function of Gate Rollers

Gate rollers serve as important parts that keep sliding gates running smoothly. These round components usually sit on brackets along both the top and bottom of the gate, allowing it to move horizontally across tracks without getting misaligned. Good quality rollers spread out the weight of the gate so there's less friction where metal meets metal something that matters a lot in factories and warehouses. A recent look at how sliding gates work showed that when companies install correctly sized rollers, their gate systems tend to last about 70% longer than those with smaller ones. What these rollers actually do is stop the gate from swaying sideways, cut down on damage to nearby parts, and maintain proper space between the moving gate and whatever supports it.

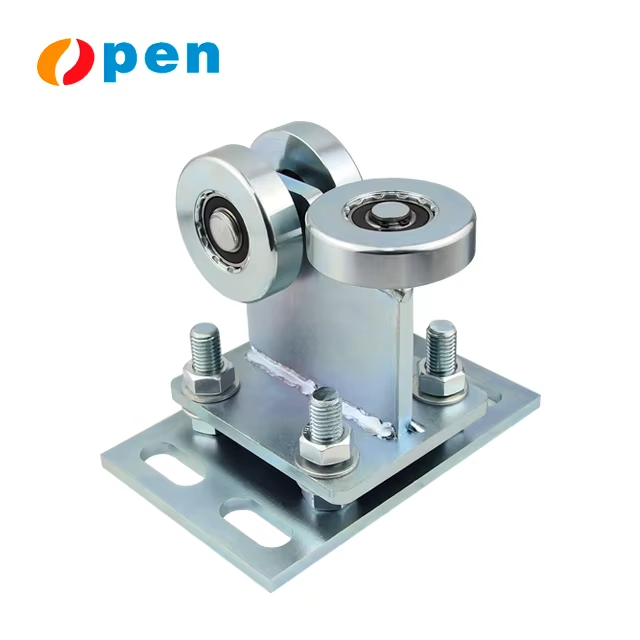

Key Components and Mechanism Overview

A gate roller’s effectiveness depends on three core elements:

- Bearing assembly: Stainless steel ball bearings reduce rotational resistance

- Load wheel: Polymer or reinforced nylon exterior withstands repeated compression

- Mounting bracket: Galvanized steel housing provides structural support

The mechanism converts horizontal pushing forces into smooth rolling motion through balanced weight distribution. Sealed lubrication chambers within roller assemblies maintain performance in outdoor environments, while tapered wheel designs automatically correct minor track misalignments during operation.

Types of Gate Rollers for Different Industrial Applications

Wheeled Gate Rollers vs. Slide Rollers

Gate rollers with wheels work on tracks mounted to the ground, making them good choices for lighter duty stuff such as home driveways or getting into warehouses. Then there are slide rollers too, especially those cantilever types that don't need ground tracks at all because they hang from above instead. This works really well when dealing with rough ground or places where snow builds up. According to research published in 2023 looking at different kinds of industrial gates, companies saw about 40 percent less money spent fixing tracks when they switched to these cantilever designs over regular wheeled ones. Makes sense why some businesses might prefer this approach.

Heavy-Duty Rollers for Commercial Gates

Heavy duty rollers built for industrial environments can handle gates that weigh well over 15,000 pounds according to the Industrial Hardware Report from 2024. What makes these systems so durable? They typically have double bearing designs which spread out the weight better across all parts, reducing how much each component gets worn down over time. Take container terminals at busy seaports for instance. One major manufacturer reports their commercial grade rollers survive upwards of 500 operations per day in these harsh conditions. This kind of usage means these specialized rollers last anywhere between 8 to 10 extra years when compared with regular models, making them a smart long term investment despite higher upfront costs.

Material Variants: Steel, Nylon, and Composite Rollers

| Material | Best For | Load Capacity | Durability |

|---|---|---|---|

| Steel | High-security facilities | 20,000+ lbs | Resists deformation |

| Nylon | Quiet operations | 8,000 lbs | Corrosion-resistant |

| Composite | Chemical plants | 12,000 lbs | UV/weather-proof |

Steel remains the default for extreme loads, while nylon’s noise reduction suits hospitals, and composites excel in coastal or corrosive settings.

Benefits of Using High-Quality Gate Rollers in B2B Settings

Improved Durability and Load Capacity

Gate rollers built for industrial use come in hardened steel or nylon composite materials and can handle weights over 8,000 pounds according to tests published last year in the Industrial Engineering Journal. What makes these rollers special is their ability to spread the load across entire gate tracks instead of concentrating pressure at single points where tracks tend to bend or warp over time. Facilities dealing with heavy machinery benefit greatly from rollers featuring axle shafts that are about 30 percent thicker than regular ones. These upgraded versions stay aligned even during constant operations throughout day and night shifts. Real world testing shows they last nearly three times longer than standard models before needing replacement.

Reduced Maintenance and Operational Downtime

Rollers that are precision engineered can cut down maintenance expenses at logistics centers by roughly 38% each year simply because they generate less wear from friction. The sealed bearings need about half as much lubrication as their open race counterparts do, which makes sense when thinking about long term savings. And let's not forget those special coatings that resist corrosion these days really help out facilities near coastlines where salt air would otherwise cause all sorts of problems. According to recent findings published in Materials Handling Review last year, this kind of reliability actually adds around 200 extra operating hours annually for each gate system across different industries. We're talking about real world benefits here based on observations from nearly fifty plants throughout the country.

How to Choose the Right Gate Roller for Your Application

Assessing Weight, Size, and Usage Frequency

The first thing to do is figure out what the gate weighs overall along with its size measurements. Most industrial style gates will tip the scales at over 1,100 pounds or around 500 kilograms, so they need those heavy duty roller systems with dual bearings built in. These help spread out the weight properly across the gate and cut down on all that annoying friction when opening and closing. If we're talking about smaller gates below 600 pounds though, sometimes composite material rollers work just fine for places that don't see too much action commercially speaking. Now when it comes to really busy locations where the gate opens and closes fifty times or more each day, steel rollers become essential equipment. Experience shows these metal options tend to hold up anywhere from three to four times longer compared to their nylon counterparts whenever there's constant back and forth movement happening throughout the day.

Environmental Factors: Outdoor Exposure and Corrosion Resistance

When setting things up outdoors near coasts or in really damp areas, stainless steel rollers are pretty much a must. According to the FAC Material Study, these bad boys only corrode about 72% less compared to regular galvanized options after five whole years out there. Now if we're talking about places where it gets seriously cold, nylon coated rollers work wonders against ice accumulation problems. They keep moving even when temps dip down to around -22 degrees Fahrenheit (-30 Celsius), which is actually pretty impressive considering what happens to most materials in those conditions. And don't forget about those UV stabilized tracks either. Without them, prolonged exposure to sunlight will eventually warp everything beyond repair, especially over time as seasons change repeatedly.

Compatibility with Existing Gate Systems

Before installing anything, make sure those roller measurements actually fit with what's already there on the gate track and between brackets. If there's even a 2 inch difference in alignment, things start wearing down much faster, about maybe around 40% quicker according to some tests, plus the whole thing moves all over the place unpredictably. Always look at what the manufacturer says about which rails go with which rollers. Most V track setups need those special grooved ones, whereas regular flat tracks will take standard round rollers just fine. When replacing old parts instead of buying new hardware, double check if the existing bolt holes line up and whether the axle size matches up too. Getting this right from the start saves money later when nobody wants to tear everything apart again.

FAQs about Gate Rollers

What are the main types of gate rollers?

There are wheeled gate rollers for ground tracks and slide rollers, including cantilever rollers that don't require ground tracks.

How do I determine the right gate roller for my application?

Assess the gate's weight, usage frequency, and environmental factors such as exposure to the elements when selecting a gate roller.

Why choose steel, nylon, or composite gate rollers?

Steel is suitable for high-security and heavy-duty applications, nylon is excellent for quiet operations, and composites are ideal for corrosive environments.

What benefits do high-quality gate rollers offer in industrial settings?

They improve durability, load capacity, and reduce maintenance costs, ultimately leading to minimized operational downtime.