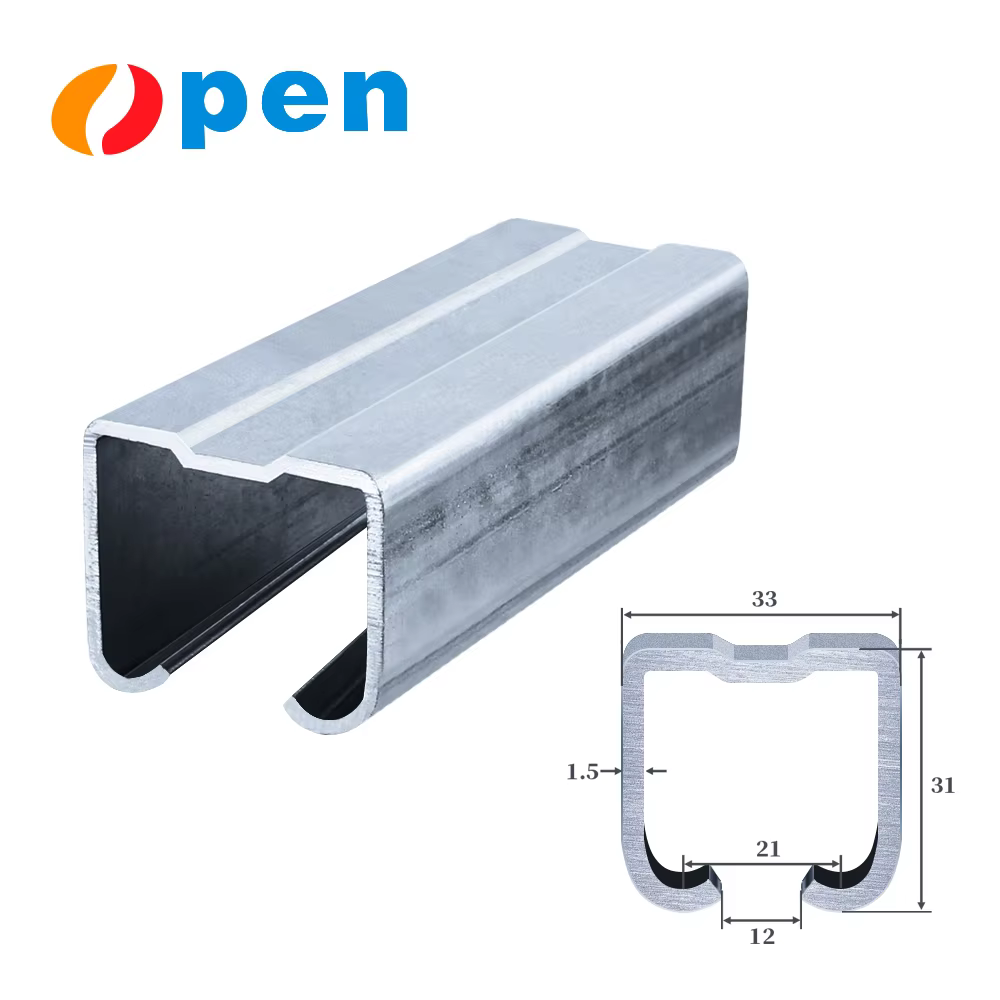

Zhejiang Openg Electromechanical Technology Co., Ltd. offers sliding gate tracks with anticorrosion coating, providing long-term protection against rust and degradation, especially in humid, coastal, or industrial environments where corrosion is a common concern. The anticorrosion coating is applied using advanced techniques, such as hot-dip galvanizing, epoxy coating, or powder coating, depending on the specific environmental conditions the track will face. Hot-dip galvanizing creates a zinc layer that acts as a sacrificial barrier, preventing moisture and corrosive substances from reaching the underlying steel. Epoxy and powder coatings, on the other hand, form a tough, impermeable film that resists chemicals, salt spray, and UV rays. The coating process is carefully controlled to ensure uniform coverage, even on edges and corners, which are often vulnerable to corrosion. This attention to detail ensures that the sliding gate track maintains its structural integrity and appearance over time, reducing the need for frequent replacements. The anticorrosion coating also contributes to the smooth operation of the gate, as a corrosion-free track minimizes friction and prevents the buildup of rust particles that can damage the gate wheels. Whether the track is installed outdoors, near the sea, or in an industrial area with chemical exposure, our sliding gate tracks with anticorrosion coating offer reliable performance and extended service life, making them a cost-effective choice for long-term installations.