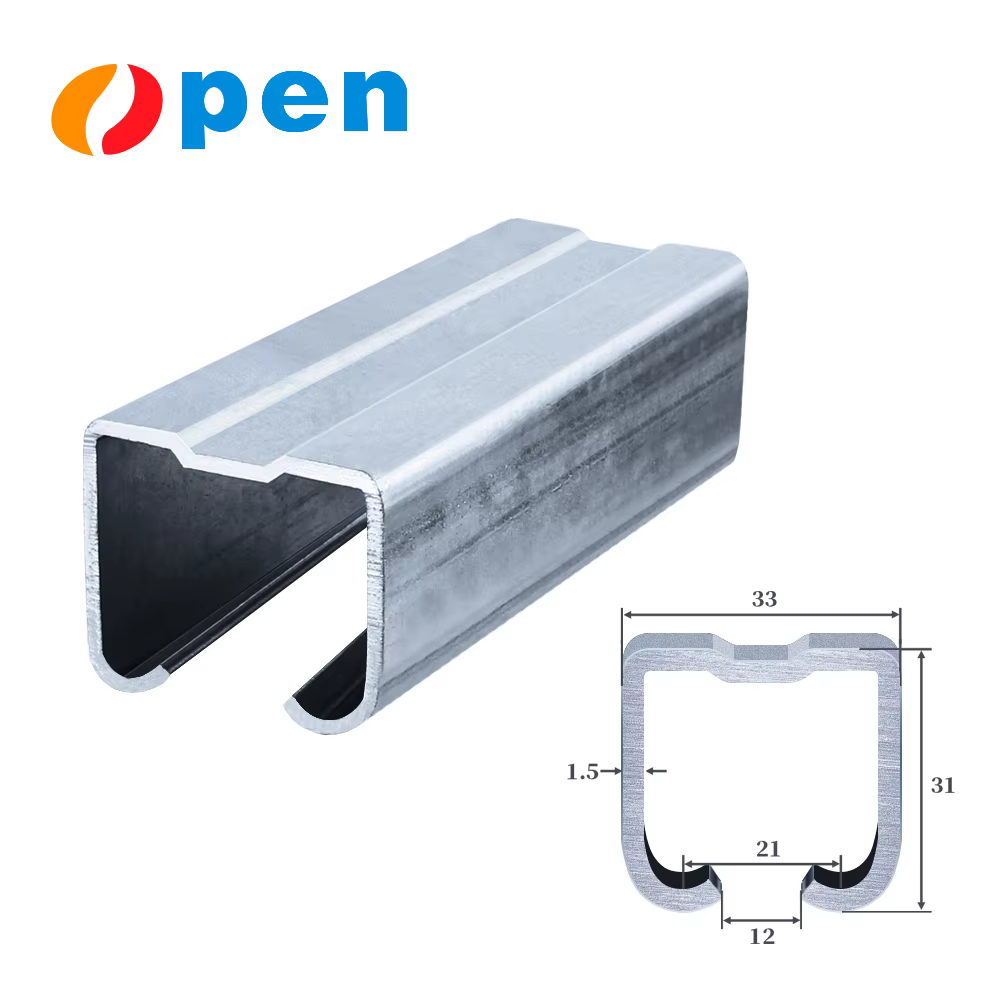

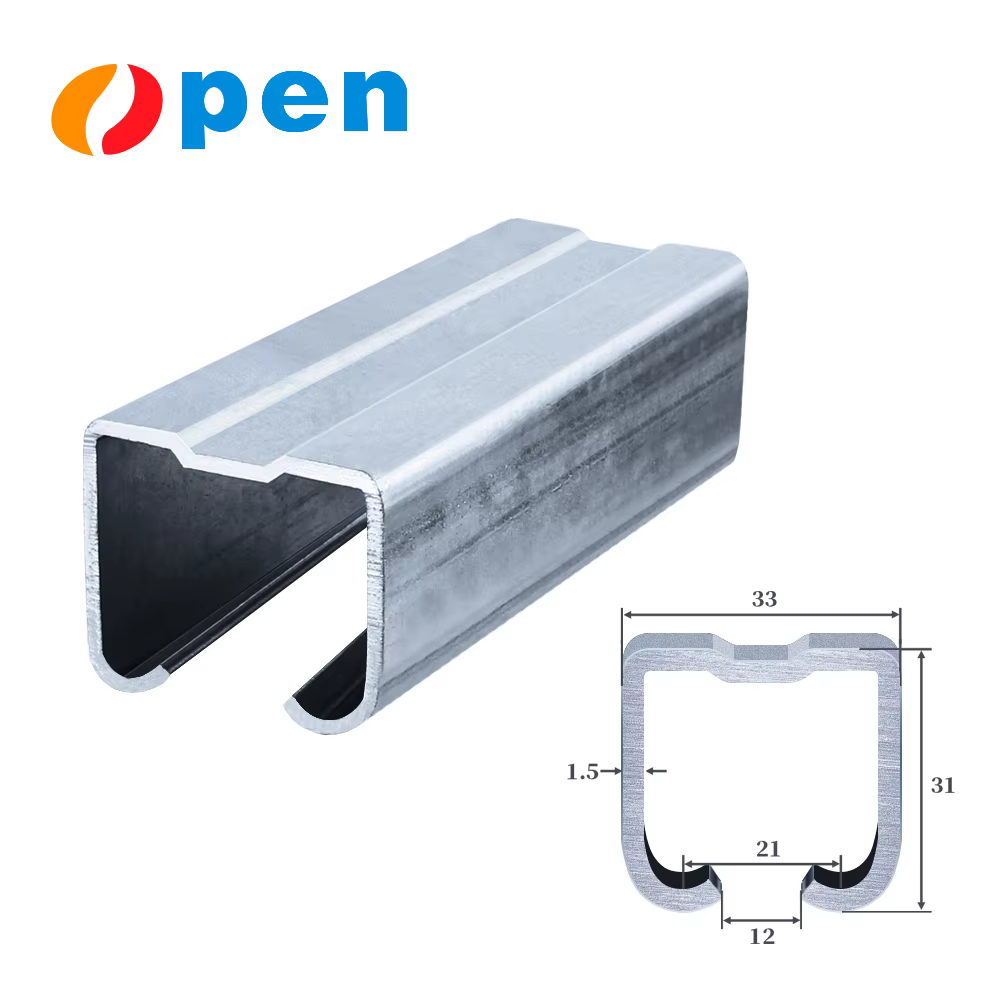

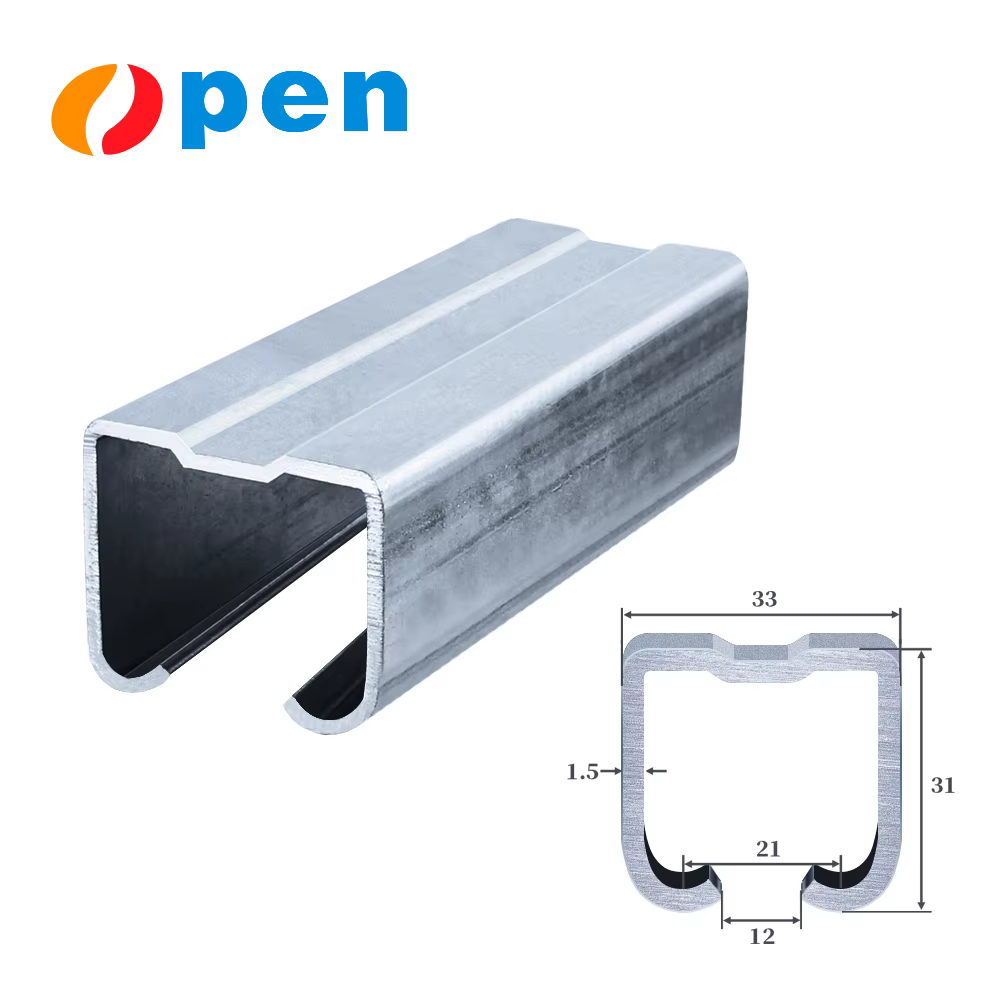

For sliding patio doors, the company offers heavy-duty sliding door rollers that combine functionality with durability. These rollers are specifically designed to support the weight of patio doors while ensuring smooth and quiet operation. Made from high-quality steel or zinc galvanized materials, they feature Y/V/U groove designs that enhance stability and reduce friction. The rollers are built to withstand regular use and environmental factors, providing long-term reliability for residential and commercial patio door applications. With their heavy-duty construction, they can handle high load capacities, ensuring that sliding patio doors operate smoothly and safely for years to come.